QR Code

About Us

Products

Contact Us

Phone

E-mail

Address

No. 22, Hongyuan Road, Guangzhou, Guangdong Province, China

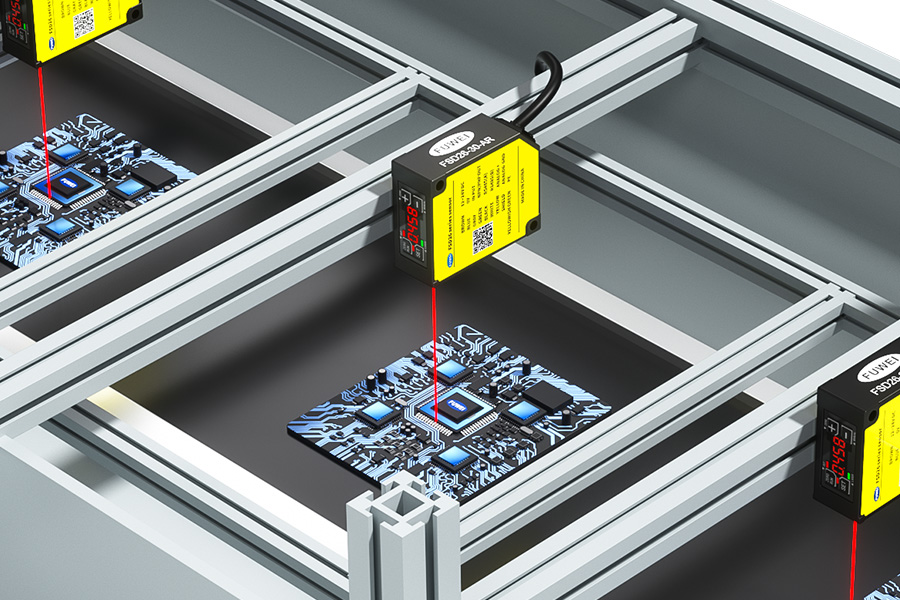

In industrial automation, precision manufacturing and other fields, laser displacement sensors are the core equipment to ensure production efficiency and product quality. However, traditional sensors often face two major pain points: it is difficult to balance high accuracy and high sampling speed, and the lack of flexible adaptability in complex scenarios. The newly launched FSD26 series laser displacement sensors from Fuwei Electronics redefine the performance benchmark of industrial measurement with ±0.1% F.S. linear accuracy, 3kHz high-speed sampling and intelligent networking functions.

First, ± 0.1% F.S. accuracy + 3kHz high-speed sampling: how can you get both?

In semiconductor testing, precision machining and other scenarios, micron-level errors may lead to product obsolescence, FSD26 series through the optimization of the laser transmitter module and high sensitivity receiver system, linear accuracy of ± 0.1% F.S., even in the complex light environment, but also a stable output of accurate data.

At the same time, its 3kHz ultra-high-frequency sampling capability can capture the displacement changes of high-speed moving objects in real time, such as dynamic monitoring of stamping presses, conveyor belt sorting and other scenarios, bid farewell to the control deviation caused by data delay, and truly realize the “high-precision” and “high-efficiency” win-win. Win-win.

Second, 4-key control + LED screen: complex parameter settings can be done with one key?

Traditional sensor parameter debugging relies on PC software or cumbersome key combinations, which is extremely unfriendly to field engineers.FSD26 series innovatively adopts a four-position LED display + four functional keys design, threshold setting, range switching, output mode selection and other operations can be completed on-site with a single key, without the need for additional equipment support.

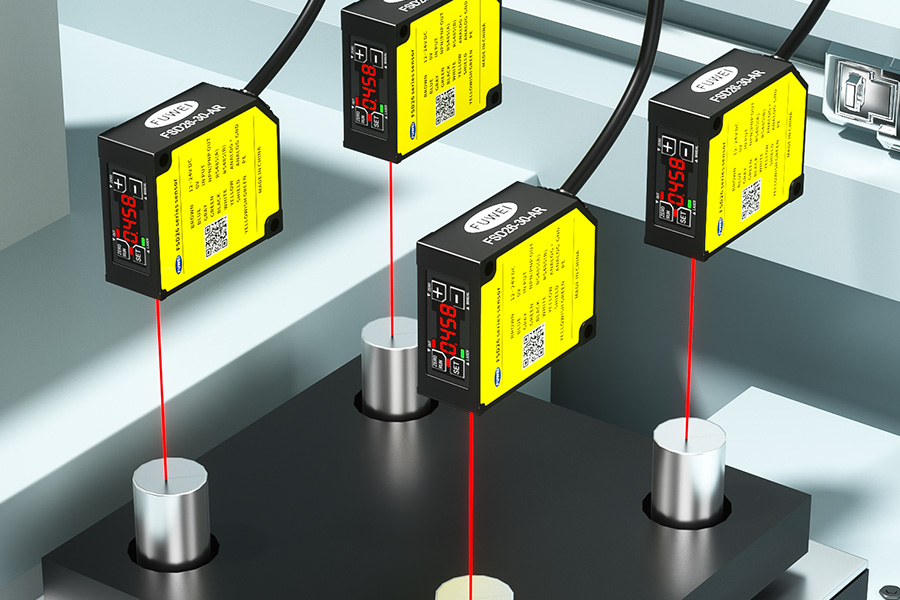

Third, 4-20mA/0-10V dual-mode output + RS485 networking: how to get through the “last kilometer” of the smart factory?

In order to meet the needs of diverse industrial interfaces, FSD26 series provides dual output modes of analog current (4-20mA) and voltage (0-10V), which can be flexibly adapted to PLCs, industrial controllers and other mainstream devices. More breakthrough integrated RS485 communication interface, support Modbus RTU protocol, a single network can be grouped 255 devices, to achieve multi-sensor data centralized management and remote control.

In the lithium production line, users can simultaneously monitor hundreds of core thickness inspection points through a host, real-time data uploaded to the MES system, to build a “measurement-control-analysis” closed-loop, providing hard-core support for the intelligent factory cost reduction and efficiency.

Measurement and control of an integrated design: how to make the sensor into an “all-round housekeeper”?

FSD26 series breaks the limitation of single function of traditional sensors, integrating analog output, switching control and RS485 communication. Its built-in comparator function can be preset alarm thresholds, directly triggering the action of external devices (such as robots, alarm lights).

For example, in the 3C electronic assembly line, when the screen thickness is detected to be out of tolerance, the sensor can synchronize the output of the switch signal to drive the robotic arm to automatically reject the defective products, compressing the response time of “perception-decision-execution” to milliseconds.

Conclusion: Enabling Intelligent Manufacturing with Hardcore Technology

With ±0.1% accuracy, 3kHz high-speed response, intelligent networking and humanized design, FSD26 series laser displacement sensors can be your reliable partner for intelligent upgrading with stable performance, no matter whether you are pursuing micron-level precision inspection scenarios or dynamic working conditions that require high-speed response.

Contact us now for customized solutions for your industry!

No. 22, Hongyuan Road, Guangzhou, Guangdong Province, China

Copyright © 2024 Guangzhou Fuwei Electronic Technology Co., Ltd. All Rights Reserved.

Links | Sitemap | RSS | XML | Privacy Policy |