QR Code

About Us

Products

Contact Us

Phone

E-mail

Address

No. 22, Hongyuan Road, Guangzhou, Guangdong Province, China

In the field of modern industrial automation, precision detection technology is a core component in ensuring product quality and improving production efficiency. Fuwei Electronics' CMOS-type miniature laser displacement sensor FSD22, with its cutting-edge technical configuration and flexible application capabilities, has become an ideal detection tool for scenarios such as electronics manufacturing and precision assembly. This sensor not only integrates high-precision hardware and algorithmic advantages but also features a rich set of functional designs to meet the diverse needs of complex industrial environments, providing a solid foundation for enterprises to achieve intelligent production.

Core Technology: Dual Assurance of High Precision and Reliability

The outstanding performance of Fuwei Electronics' CMOS-type miniature laser displacement sensor FSD22 stems from its high-precision CMOS image sensor and the company's proprietary unique algorithms. This technological combination breaks through the precision limitations of traditional displacement detection devices, enabling the distance-setting reflective sensor to achieve an unprecedented measurement precision of 1/100mm (0.01mm). Whether for dimension inspection of small components or position tracking during high-speed movement, the sensor maintains stable measurement performance, providing reliable data support for critical stages in industrial production.

Notably, the sensor's high precision is not limited to specific scenarios. Through optimized optical design and algorithm compensation mechanisms, it maintains measurement stability under varying lighting conditions and temperature fluctuations, effectively reducing external interference on detection results. This adaptable technical feature enables it to confidently meet the usage requirements of complex environments such as electronic manufacturing workshops.

Application Scenarios: Covering Key Inspection Processes in Electronic Manufacturing

The application scenarios for Fuwei Electronics' CMOS-type miniature laser displacement sensors are extensive, particularly in the electronic manufacturing field, where they demonstrate significant advantages. The following are several core application directions:

In substrate warpage detection, the sensor can precisely capture minor deformations in the substrate during processing or welding. For precision circuit boards, even 0.01mm of warpage can lead to subsequent assembly failures. The sensor's high-precision measurement capability enables real-time monitoring of warpage data, helping production lines adjust process parameters promptly to avoid batch-level product defects.

For lead frame overlap detection, the sensor uses non-contact measurement to quickly identify overlap issues in lead frames during transportation or stacking. Since lead frames are lightweight and have delicate structures, traditional contact-based detection methods can cause damage. Laser displacement technology ensures detection sensitivity while avoiding physical impact on the workpiece, significantly improving detection efficiency and yield rates.

In the front/back determination process for electronic component housings, the sensor can quickly distinguish the front/back direction of components by identifying subtle structural differences on the housing surface (such as interface positions and texture features). Integrating this functionality into automated production lines can replace manual sorting, not only improving determination accuracy but also significantly enhancing production throughput.

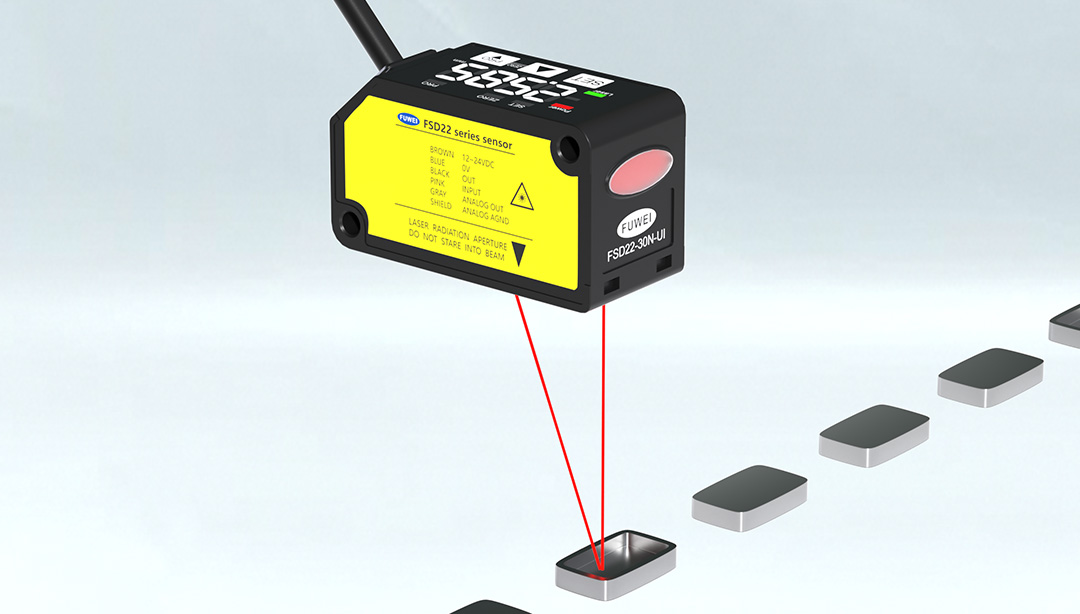

Additionally, in the detection of gasket presence, the sensor leverages its high-precision distance measurement capability to accurately identify gasket omissions on high-speed conveyor belts. For industries with stringent requirements for assembly integrity, such as automotive electronics and consumer electronics, this functionality effectively reduces the risk of product failures caused by missing components.

Data Output and Integration: Flexible Adaptation to Industrial Automation Systems

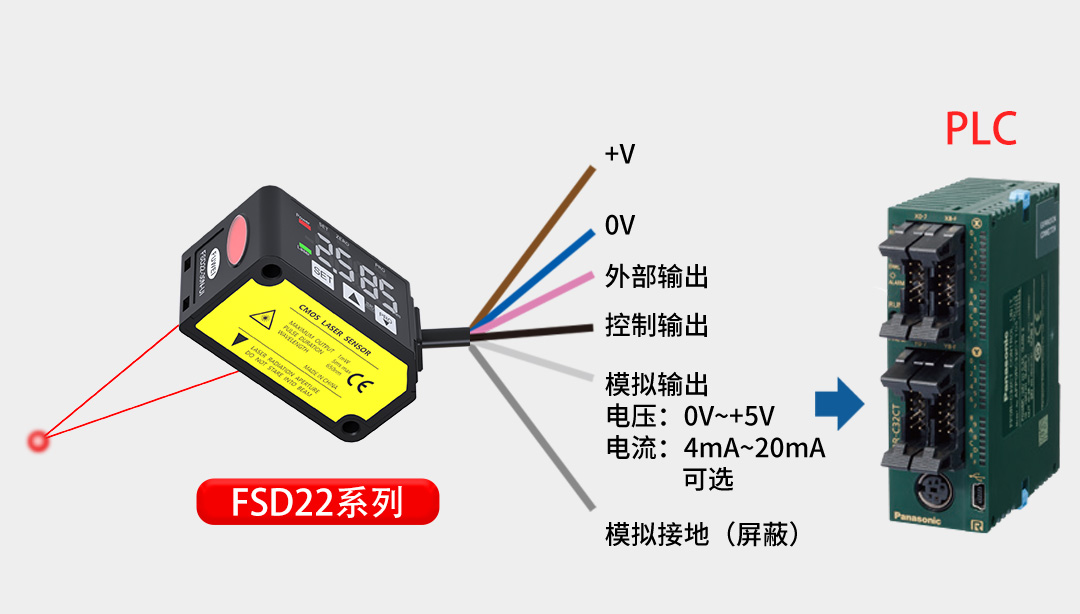

To meet the integration requirements of industrial automation, Fuwei Electronics' CMOS-type miniature laser displacement sensors demonstrate exceptional flexibility in data interaction. The sensors support analog output (0-5V/4-20mA), enabling direct connectivity with upper-level devices such as PLCs and data acquisition modules for real-time transmission of measurement data. Additionally, they can display measurement values in millimeters, allowing operators to quickly read critical information on-site.

More importantly, the sensor's data analysis capabilities further enhance its application value. It supports various computational processing of measurement data and can store historical records, providing data support for quality traceability and process optimization on production lines. For example, by analyzing the gasket inspection data of a batch of products, companies can trace back to the specific production period's equipment status, providing reference for preventive maintenance.

For scenarios requiring multi-sensor collaboration, the sensor's expandability is equally outstanding. Using standardized communication protocols, it can seamlessly integrate into industrial IoT systems, forming a coordinated network with other detection devices and control systems to build a comprehensive production monitoring network. This high level of integration allows companies to flexibly configure detection solutions based on their production line scale, reducing the technical barriers for system upgrades.

No. 22, Hongyuan Road, Guangzhou, Guangdong Province, China

Copyright © 2024 Guangzhou Fuwei Electronic Technology Co., Ltd. All Rights Reserved.

Links | Sitemap | RSS | XML | Privacy Policy |