QR Code

About Us

Products

Contact Us

Phone

E-mail

Address

No. 22, Hongyuan Road, Guangzhou, Guangdong Province, China

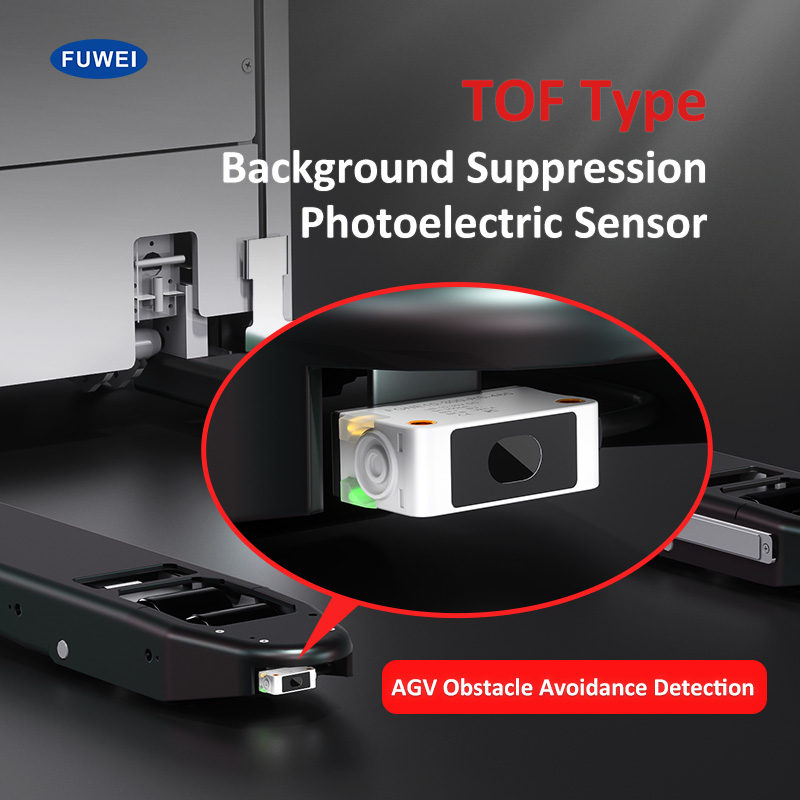

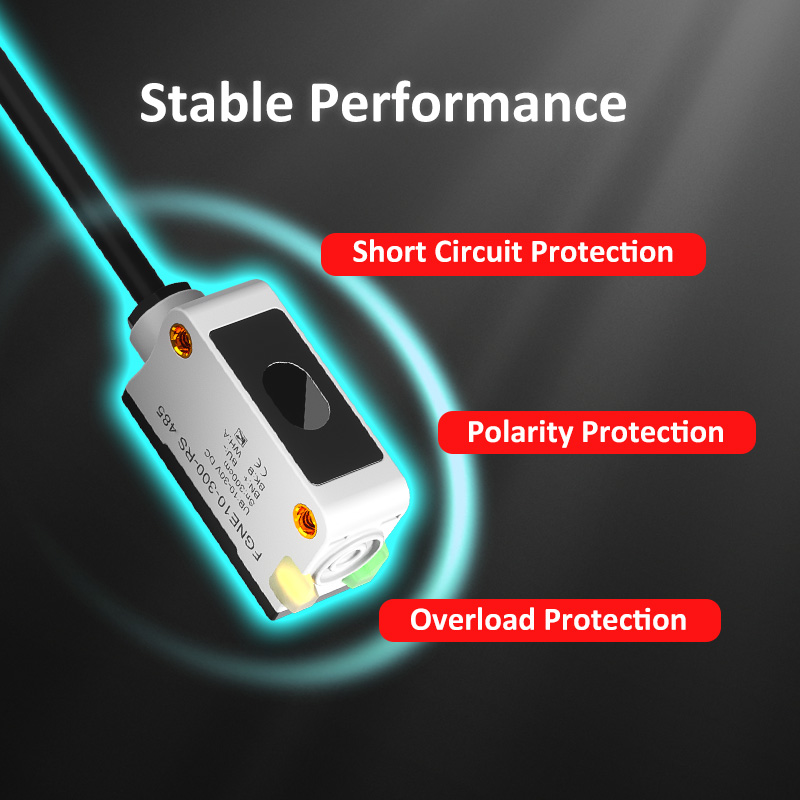

In the wave of Industry 4.0 and intelligent manufacturing, the innovation of perception technology is reshaping the underlying logic of the production scene. As the “sensory nerve” of industrial automation systems, the performance of photoelectric sensors directly determines the response speed and scene adaptability of equipment. The FGNE10-300-RS485TOF photoelectric sensor launched by Fuwei Electronics has reconstructed the boundary of industrial perception with breakthrough technology, providing more accurate and stable solutions for intelligent factories, AGV robots and other scenes.

I. 0.5-300cm to cover the needs of the whole scene

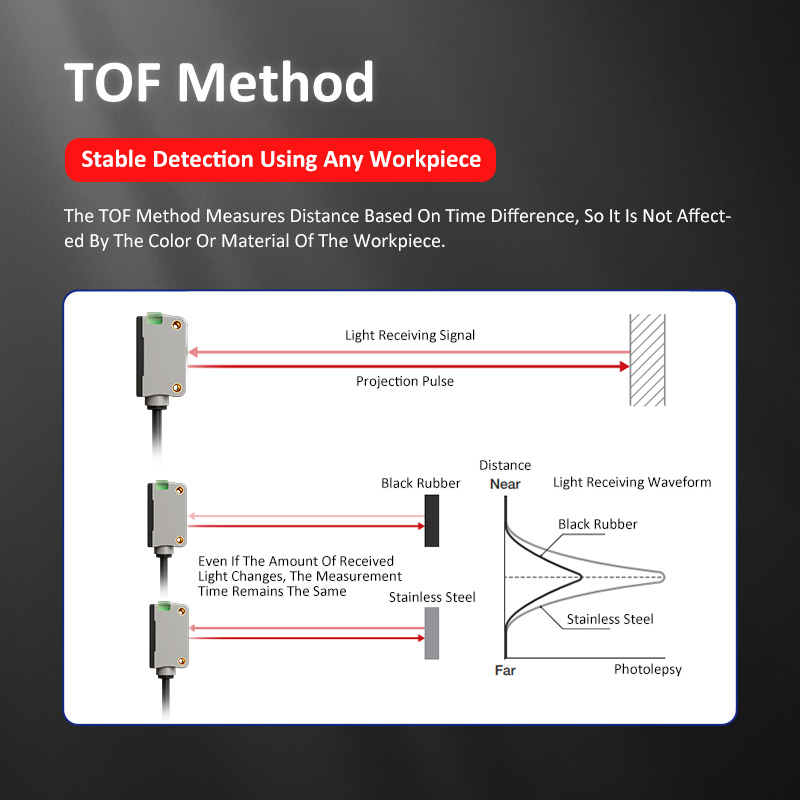

Traditional photoelectric sensors are often forced to be “deployed in different scenes” due to range limitations, resulting in poor equipment compatibility and rising maintenance costs.FGNE10-300-RS485TOF extends the range to a wide range of 0.5-300cm through innovative TOF (Time of Flight) ranging technology, realizing full coverage of long-distance monitoring from macro positioning to long-distance monitoring. long-distance monitoring. In robotic arm gripping scenarios, the 0.5cm accurate identification can ensure the assembly accuracy of tiny parts; while in AGV robot obstacle avoidance scenarios, the 300cm ultra-long detection distance significantly improves mobile safety redundancy. Multi-purpose machine, completely bid farewell to the frequent replacement of sensors due to scene switching.

IP67 protection + anti-sunlight design

Outdoor and complex industrial environments have long constrained the application of photoelectric sensors boundaries, FGNE10-300-RS485TOF IP67 protection to create a “body of steel” - fully sealed structure to resist dust, water spray, corrosion-resistant materials, adaptable to acid and alkali environments, with corrosion-resistant materials. Adapt to acid and alkali environments, with anti-sunlight interference technology, even in the midday direct light, can still be a stable output signal. This feature makes it show excellent reliability in extreme scenes such as AGV navigation in open-air warehousing and high-temperature production line in metallurgical industry, truly realizing “all-weather combat”.

Third, the synergistic evolution of filter + 360 ° LED

Traditional sensors often cause misjudgment due to ambient light interference or poor visibility of working conditions. The technical team of Fuwei Electronics creatively puts forward the concept of “perception visualization”: the built-in high-quality light filter can shield 99% of stray light interference, which improves the detection accuracy to the millimeter level; at the same time, it is equipped with high-brightness 360° ring LEDs, which dynamically prompts the status of the equipment through the red/blue dual-color. In the high-speed production line, engineers can instantly determine the sensor operating mode through the color of the light, significantly reducing troubleshooting time. This “human-computer interactive design” allows cold sensors for the first time with “communication temperature”.

From single-point detection to system-level empowerment

The value of FGNE10-300-RS485TOF not only lies in the hardware breakthrough, but also in its deep adaptation to industrial scenarios:

Robotic arm positioning: 0.1ms response speed matches the beat of high-speed production lines, ensuring micron-level repeatable positioning accuracy;

AGV obstacle avoidance system: RS485 interface supports multi-sensor networking, building a 270° three-dimensional protective barrier;

Intelligent warehousing: copper thread mounting design is compatible with various types of brackets, quickly deployed in the three-dimensional warehouse beam.

In the actual application of an auto parts factory in Dongguan, this type of photoelectric sensor helps the AGV fleet to improve the response speed of obstacle avoidance by 40%, and at the same time reduces the frequency of robotic arm shutdown and maintenance by 75%, which verifies its core value in the chain of “sensing-decision-making-execution”.

With the FGNE10-300-RS485TOF photoelectric sensor, Foway Electronics focuses its technological innovation on the three dimensions of range, environmental adaptability and human-machine interaction, which not only redefines the standard of industrial perception, but also promotes the evolution of AGVs, robotic arms and other equipment to a higher level of autonomous decision-making.

No. 22, Hongyuan Road, Guangzhou, Guangdong Province, China

Copyright © 2024 Guangzhou Fuwei Electronic Technology Co., Ltd. All Rights Reserved.

Links | Sitemap | RSS | XML | Privacy Policy |