QR Code

About Us

Products

Contact Us

Phone

E-mail

Address

No. 22, Hongyuan Road, Guangzhou, Guangdong Province, China

In modern industrial production, the accuracy and stability of the inspection process directly determine product quality and production efficiency. However, many companies still face challenging inspection issues: frequent changes in object color on the assembly line lead to sensor misjudgments, hollow or uneven surfaces of workpieces are difficult to precisely capture with a single light spot, and inspection data fluctuates wildly under complex conditions... These issues not only slow down production but may also result in defective products entering the market in bulk. The bar-shaped laser sensor FJN10-05NI developed by Fuwei Electronics, with its three core advantages, is emerging as the key solution to these challenges.

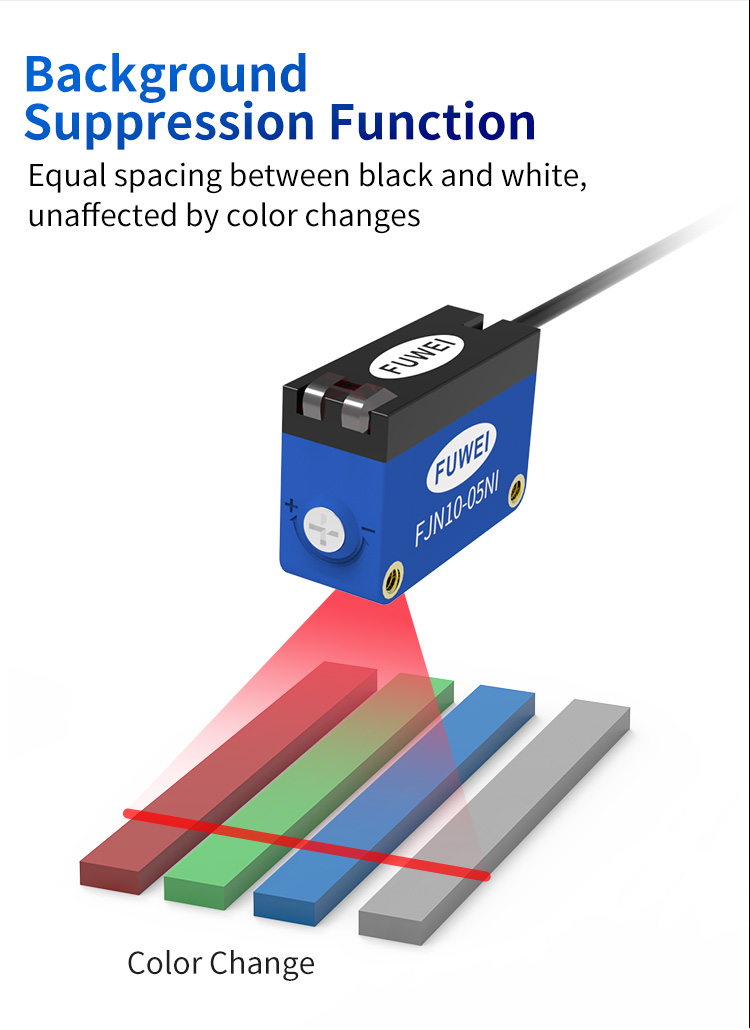

Breakthrough design of background suppression functionality eliminates color as a detection obstacle. Traditional laser sensors often experience detection distance deviations when faced with black-and-white or light-dark colored objects due to differences in reflectivity. For example, when detecting black plastic parts, the response distance is more than 30% shorter than that of white workpieces, leading to frequent production line shutdowns for calibration. The FJN10-05NI, equipped with a dual-channel background suppression algorithm, dynamically adjusts laser emission power and reception sensitivity to achieve precise black-and-white equal-distance detection. Within the 30-500mm detection range, regardless of whether the workpiece is a shiny metal surface, matte plastic, or a colored coating, as long as the actual distance is consistent, the sensor can stably output a switch signal. After a certain automotive parts manufacturer adopted this sensor, the misjudgment rate for detecting colored wire harness terminals dropped from 12% to 0.3%, with daily production capacity increasing by nearly 2,000 units.

The innovative design of the visible laser bar spot provides the optimal solution for special surface detection. Traditional single-point laser sensors often fail to detect objects when faced with workpieces such as gear teeth, perforated plates, or corrugated plates, as the spot only covers a single point. When the spot falls precisely on a hollow area or the lowest point of a depression, the sensor may incorrectly judge it as “no object.” The FJN10-05NI employs a special aspherical optical lens group to converge the laser into a linear spot measuring 10mm in length and 0.8mm in width, expanding the detection area by 12 times compared to single-point sensors. When detecting heat dissipation holes in the metal frame of a smartphone, the linear spot can simultaneously cover 3–4 holes and the surrounding solid areas. By analyzing the distribution of reflected light, the sensor determines whether the workpiece is present, achieving a detection accuracy rate of 99.97%.

The detection stability provided by the special optical design ensures the sensor's continuous reliability in complex operating conditions. The spot shape of traditional sensors is easily affected by temperature — when the ambient temperature rises from 25°C to 60°C, the single-point spot may shift or defocus due to thermal expansion and contraction of the lens, causing the detection threshold to drift. The FJN10-05NI's lens assembly uses low-expansion microcrystalline glass material combined with a metal housing structure, ensuring that the spot shape changes by less than 0.05mm within the temperature range of -25°C to 70°C. A photovoltaic module manufacturer used it for silicon wafer microcrack detection in a workshop with high dust concentration and a day-night temperature difference of 15°C. After continuous operation for 3,000 hours, no false alarms occurred, reducing maintenance frequency by 90% compared to the previous equipment.

As the “sensory nerve” of industrial automation, the FJN10-05NI also features an IP67 protection rating, capable of withstanding oil contamination and water mist, while supporting NPN/PNP output mode switching and compatibility with mainstream PLC control systems. Currently, this sensor is widely applied in 3C electronics, automotive manufacturing, packaging, and printing industries, helping nearly 100 companies overcome detection bottlenecks.

As industrial production transitions toward high precision and flexibility, performance differences in detection equipment are becoming a key factor in competitive advantage. FUWELL Electronics' FJN10-05NI addresses three major challenges—color interference, complex surfaces, and harsh operating conditions—through innovative optical design, equipping production lines with “eagle eyes” to ensure precise and error-free detection every time.

No. 22, Hongyuan Road, Guangzhou, Guangdong Province, China

Copyright © 2024 Guangzhou Fuwei Electronic Technology Co., Ltd. All Rights Reserved.

Links | Sitemap | RSS | XML | Privacy Policy |