QR Code

About Us

Products

Contact Us

Phone

E-mail

Address

No. 22, Hongyuan Road, Guangzhou, Guangdong Province, China

Sheet metal is a commonly used stamping process in the field of automotive components. Products processed through sheet metal technology are called sheet metal parts. The term "sheet metal parts" generally refers to different things in different industries. Their quality and accuracy are crucial to the performance of the entire product. However, traditional methods for defect detection and dimensional measurement of sheet metal parts often suffer from issues such as low efficiency and insufficient accuracy.

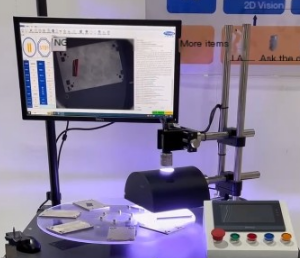

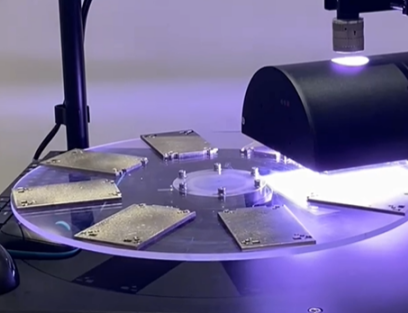

A well-known automobile manufacturing enterprise has successfully applied the Fuwei intelligent collaborative robot to achieve automation of defect detection and dimensional measurement for sheet metal parts. Through high-precision visual recognition technology, comprehensive inspection of sheet metal parts is carried out.

In terms of defect detection, the Fuwei intelligent collaborative robot, equipped with a 3D camera and deep learning algorithms, can accurately identify various defects on the surface of sheet metal parts, such as cracks, dents, scratches, etc. The robot can autonomously plan its path, conduct a comprehensive scan of the sheet metal parts, and transmit the detected defect information to the control system in real time. Based on the type and extent of the defects, the control system automatically determines whether further processing or scrap is required, greatly improving detection efficiency and accuracy.

In terms of dimensional measurement, the Fuwei intelligent collaborative robot utilizes laser ranging sensors and 3D vision technology to precisely measure the dimensions of sheet metal parts. The robot can autonomously position and grasp the sheet metal parts, acquire their 3D shape data through laser scanning, and compare it with preset standard dimensions. The measurement data can be transmitted in real-time to the quality control department via the network for further analysis and processing.

By introducing the Fuwei intelligent collaborative robot, the automobile manufacturing enterprise has not only improved the efficiency and accuracy of sheet metal part inspection but also reduced the errors and labor intensity of manual inspection. Simultaneously, the application of automated inspection and measurement systems has provided the enterprise with more reliable and comprehensive quality control methods, contributing to the enhancement of overall product quality and market competitiveness.

No. 22, Hongyuan Road, Guangzhou, Guangdong Province, China

Copyright © 2024 Guangzhou Fuwei Electronic Technology Co., Ltd. All Rights Reserved.

Links | Sitemap | RSS | XML | Privacy Policy |