QR Code

About Us

Products

Contact Us

Phone

E-mail

Address

No. 22, Hongyuan Road, Guangzhou, Guangdong Province, China

The precision manufacturing industry demands extremely high precision, stability, and efficiency from its equipment. Hybrid robots, with their versatility, high flexibility, and precise control capabilities, are gradually becoming the new darlings of this field. Below is an application case of a Fuwei Intelligent Hybrid Robot in precision manufacturing.

Case background:

A well-known automotive parts manufacturing enterprise specializes in producing high-precision and high-quality engine parts. To cope with the rapid growth of market demand and enhance product competitiveness, the enterprise has decided to introduce hybrid robots to optimize its production line and improve production efficiency and product quality.

Application scheme:

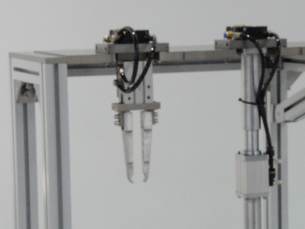

The company has introduced multiple hybrid robots for precision machining and assembly of engine components. These hybrid robots are equipped with high-precision robotic arms, advanced vision systems, and intelligent control systems, enabling precise grasping, positioning, and assembly of components.

On the production line, the hybrid robot seamlessly integrates with CNC machines and inspection equipment, forming a highly automated production line. The hybrid robot automatically completes tasks such as loading and unloading, processing, and inspecting components according to preset programs and instructions. Simultaneously, the vision system conducts real-time inspection of components to ensure that each one meets quality standards.

In addition, composite robots exhibit high flexibility and scalability. Enterprises can easily adjust the number and configuration of robots according to production needs, thereby adapting to the production of parts of different models and specifications.

Application effect:

After introducing the Fuwei intelligent hybrid robot, the production efficiency of the enterprise has been significantly improved. The automated operation of the hybrid robot reduces the tediousness and errors of manual operations, enhancing the stability and reliability of the production line. Meanwhile, the high-precision operation of the hybrid robot also ensures the stability and consistency of product quality.

In addition, the introduction of hybrid robots has reduced the production costs of enterprises. Since robots can work continuously for 24 hours, enterprises do not need to worry about personnel fatigue and turnover, thus reducing labor costs. At the same time, the efficient operation of robots has also reduced waste and loss in the production process, further lowering production costs.

No. 22, Hongyuan Road, Guangzhou, Guangdong Province, China

Copyright © 2024 Guangzhou Fuwei Electronic Technology Co., Ltd. All Rights Reserved.

Links | Sitemap | RSS | XML | Privacy Policy |