QR Code

About Us

Products

Contact Us

Phone

E-mail

Address

No. 22, Hongyuan Road, Guangzhou, Guangdong Province, China

Whether it's the minute variations in cable extrusion outer diameters, the precise positioning of wafer edge measurements, or real-time adjustments during winding alignment, traditional contact-based measurement methods can no longer meet the demands of modern production.

01 The Measurement Revolution: The Rise of Non-Contact Technology

Dimension measurement in precision manufacturing has undergone a long evolution from manual calipers to automated inspection. In the 1990s, CCD wire diameter measurement sensor technology began entering industrial applications.

This non-contact measurement technology, centered on charge-coupled devices (CCDs), was initially applied primarily to “non-contact, high-precision, in-line measurement of wire cables and optical cables.” With technological advancements, CCD sensors' measurement capabilities continued to improve. By the early 21st century, they achieved detection levels with “measurement accuracy better than 0.01 mm.”

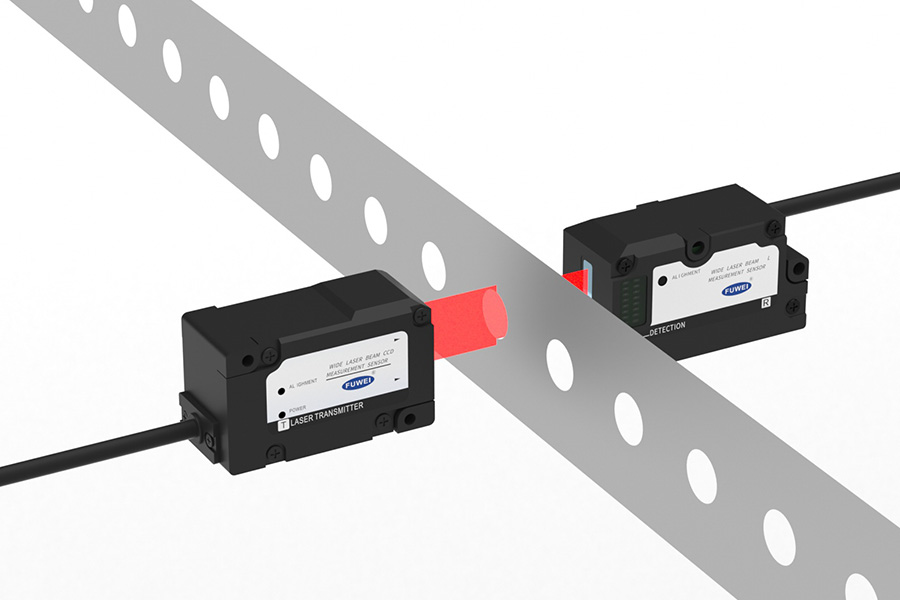

Unlike traditional measurement methods, CCD technology employs photoelectric conversion principles to transform an object's optical image into digital signals. This enables “high precision, excellent repeatability, and easy installation and adjustment.” This technological breakthrough made real-time quality monitoring on automated production lines possible.

02 Fuwei Electronics FLM-50-RS485: Redefining Measurement Standards

Addressing the dual demands for measurement precision and response speed in precision manufacturing, Fuwei Electronics' FLM-50-RS485 CCD wire diameter measurement sensor delivers an innovative solution.

This sensor integrates multiple technological advantages:

- A rapid 2ms response time ensures instant detection of high-speed moving objects on production lines; and repeatability accuracy as high as 10μm, guaranteeing highly consistent measurement results.

For installation convenience, the product features a standard M3 screw design, significantly simplifying the installation process and reducing equipment debugging time. This design detail reflects a deep understanding of actual industrial field requirements.

Unlike traditional systems requiring additional processing units, Fuwei Electronics' innovative design philosophy emphasizes “integrated measurement and control.” The FLM-50-RS485 sensor features high internal integration, reducing system complexity while enhancing overall reliability through streamlined signal chains.

03 Diverse Applications: Precision Measurement Across Scenarios

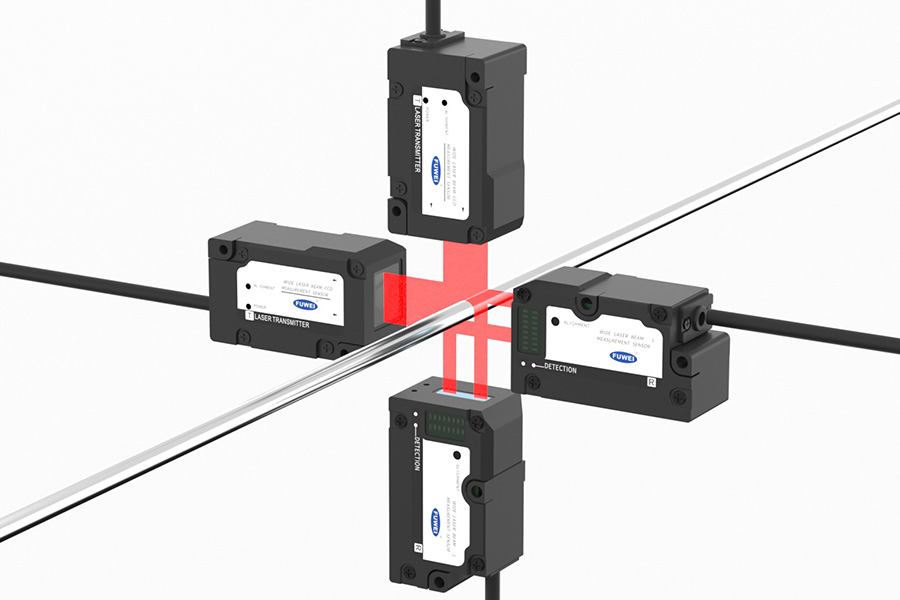

The true value of CCD wire diameter measurement sensors lies in their versatility across industrial applications. Fuwei Electronics' FLM-50-RS485 spans multiple sectors from traditional manufacturing to high-tech industries.

In foundational manufacturing, it precisely measures the inner diameter of stamped parts and the outer diameter of extruded cables, ensuring strict compliance with design specifications. For applications requiring high-precision alignment, such as roller gap measurement, the sensor delivers reliable data support.

04 Core Technology: Robust Performance Ensures Reliability

The exceptional performance of Fuwei Electronics' FLM-50-RS485 CCD wire diameter measurement sensor stems from robust support by multiple core technologies.

As production line speeds continue to increase, response time requirements for CCD wire diameter measurement sensors have advanced from millisecond to microsecond levels. Future sensors will integrate more intelligent diagnostic functions, predicting potential failures through condition monitoring to reduce unplanned downtime.

The technological trajectory demonstrated by Fuwei Electronics' FLM-50-RS485 product indicates that CCD wire diameter measurement sensors are evolving from standalone measurement tools into intelligent nodes that integrate measurement, analysis, and control.

When dimensional data for every product on the production line is captured, analyzed, and fed back in real time, manufacturing achieves a profound shift from “experience-driven” to “data-driven” operations.

No. 22, Hongyuan Road, Guangzhou, Guangdong Province, China

Copyright © 2024 Guangzhou Fuwei Electronic Technology Co., Ltd. All Rights Reserved.

Links | Sitemap | RSS | XML | Privacy Policy |