QR Code

About Us

Products

Contact Us

Phone

E-mail

Address

No. 22, Hongyuan Road, Guangzhou, Guangdong Province, China

In industrial automation, the stability and accuracy of color detection directly impact production quality and efficiency. Traditional sensors often suffer from misjudgments and poor stability when encountering production line vibrations, material displacement, or surfaces made of different materials.

So, how does an excellent color mark sensor overcome these challenges?

01 RGB Triple Light Sources, Intelligent Adaptation to Different Materials

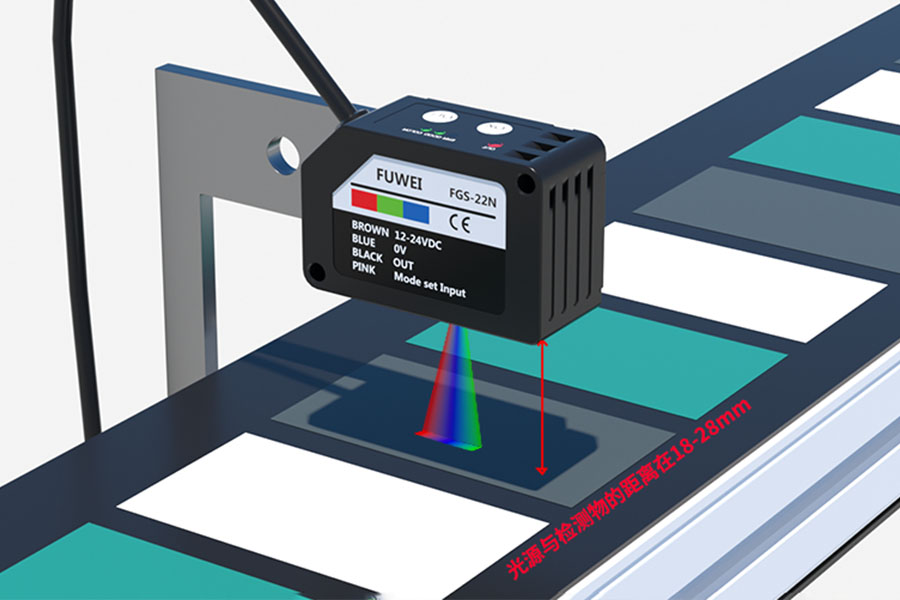

The FGS-22N series color mark sensor from Fuwei Electronics features built-in independent red, green, and blue LED light sources. It automatically selects the optimal LED combination based on the surface characteristics of the target object.

Whether detecting dark materials or highly reflective surfaces, this sensor ensures consistent detection performance.

The system employs intelligent algorithms to automatically adjust light sources, eliminating the cumbersome manual debugging required by traditional sensors. This significantly enhances production line adaptability and detection accuracy.

02 Adjustable Hysteresis Function for Strong Interference Resistance

Vibrations from production line conveyors and material displacement are common causes of detection signal fluctuations. The FGS-22N series features a manually adjustable detection hysteresis function with a range of 0.1-10mm.

This capability effectively eliminates interference from mechanical vibrations, ensuring stable detection performance even in high-speed production environments.

Operators can flexibly adjust hysteresis parameters based on actual production conditions. Simple and user-friendly, no specialized technicians are required for commissioning.

03 Precision Spot Design Prevents Background False Triggers

At the standard 23mm detection distance, the FGS-22N projects a focused rectangular spot measuring 1.5×7mm.

This narrow rectangular spot precisely covers narrow color marks like cable color rings or micro-component identifiers, effectively preventing background false triggers.

Compared to the circular spots common in traditional sensors, the rectangular spot offers clear advantages when detecting linear color marks, reducing the need for cumbersome sensor repositioning.

04 Dual-mode synchronous detection for versatile applications

The FGS-22N series supports simultaneous detection in both color mark and color modes, combining two functions into one.

Color mark mode is ideal for high-speed capture of printed mark positions, such as packaging film alignment. Color mode enables precise identification of object colors.

This unique dual-mode design allows simultaneous detection of color and light intensity, preventing false outputs even at critical positions with no background or objects at the detection edge.

05 Compact Design, Powerful Performance

The FGS-22N series color mark sensor features a compact size and weighs only approximately 104 grams, enabling easy installation without occupying excessive space.

Its response time is less than 200 microseconds, meeting the detection demands of high-speed production lines.

This series offers both NPN and PNP output models to accommodate different control system interface requirements.

Through five core technologies—light source adaptation, mechanical interference resistance, spot focusing, dual-mode fusion, and simplified operation—Fuwei Electronics' FGS-22N series redefines high-stability color detection.

It demonstrates that an exceptional color mark sensor not only resolves practical production challenges but also serves as a critical component in smart manufacturing transformation.

Looking ahead, as industrial automation demands continue to rise, technological innovations in color mark sensors will further elevate production line efficiency to new heights.

No. 22, Hongyuan Road, Guangzhou, Guangdong Province, China

Copyright © 2024 Guangzhou Fuwei Electronic Technology Co., Ltd. All Rights Reserved.

Links | Sitemap | RSS | XML | Privacy Policy |