QR Code

About Us

Products

Contact Us

Phone

E-mail

Address

No. 22, Hongyuan Road, Guangzhou, Guangdong Province, China

With the evolution of the times, the manufacturing industry is constantly moving towards intelligence, flexibility, and lean manufacturing. In the process of automation upgrade in the precision machining industry, robot technology is facing higher requirements, such as faster deployment capability, higher stability, more precise operation, more flexible adaptability, and achieving human-machine collaborative operation. Therefore, many large precision machining enterprises have chosen to use mobile collaborative robots to achieve automation upgrades, replacing manual labor to complete precise operations such as material transportation and loading and unloading, in order to improve production efficiency and quality.

Taking the precision processing industry as an example, Fuwei Intelligent has long been committed to the research and practice of precision machining automation scenarios. It is well aware of the challenges of "labor shortage and difficulty in labor", "difficulty in intelligent transformation and poor upgrading effect", "automation island and information island" obstacles, and "complex environment and difficult management", all of which to some extent constrain the sustainable development and efficiency improvement of enterprises. Fuwei Intelligence is actively seeking innovative solutions to address these pain points, in order to promote more efficient and intelligent production models for enterprises.

How to get rid of these problems?

In addition to the application of traditional industrial robotic arms, collaborative robots, and mobile robots, business owners have also realized the urgent need for a robot that can replace manual operations, replace the "hand, foot, and eye" problems of humans, achieve material grasping, flexible movement between multiple machines, and accurately place materials by identifying fixture positions. At the same time, it is also necessary to use robots and intelligent systems to organically connect various single station machine tools in order to better achieve visualization and dataization of production.

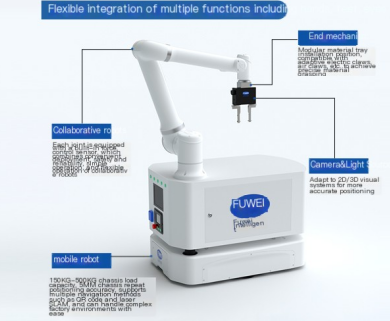

Fuwei Intelligent Composite Robot has the ability of autonomous movement, flexible grasping, and operation. The maximum operating accuracy of the composite robot is ± 0.02mm (with 3D vision)/± 0.05mm (with 2D vision), and the repetitive positioning accuracy of the collaborative robot is ± 0.02mm - ± 0.05mm. Equipped with a vision system, it can complete precise material grasping, material transportation between machines, and identify fixture positions for accurate placement.

The key is that the Fuwei intelligent composite robot combined with the scheduling system can achieve multi machine collaborative operation of different devices, achieve 7X24 round the clock production, ensure production consistency, improve production yield, reduce production costs for enterprise owners, and increase profits.

Based on the core technology of Fuwei Intelligent Composite Robot, Fuwei Intelligent provides the industry with a "matrix based flexible manufacturing production line unmanned overall solution".

This solution can rely on the standardization unit foundation of the machining production line, and according to the different production needs of users, select machining equipment through composite robots to achieve rapid and flexible production conversion of products of different processes, models, and batches. The solution is highly favored by precision machining enterprises because it can solve the pain points and problems that plague the enterprise.

Difficulties such as long deployment cycles are no longer obstacles to enterprise automation upgrades in the solution: Moying Technology's mobile collaborative robot adopts integrated control and drag and drop teaching, and can complete scene applications in as fast as 2 hours after unboxing; The entire production line renovation does not affect the normal operation of other production lines in the area, and there is no need to damage the ground. The deployment can be completed within 7 working days at the fastest, greatly saving the renovation costs of business owners.

No. 22, Hongyuan Road, Guangzhou, Guangdong Province, China

Copyright © 2024 Guangzhou Fuwei Electronic Technology Co., Ltd. All Rights Reserved.

Links | Sitemap | RSS | XML | Privacy Policy |