QR Code

About Us

Products

Contact Us

Phone

E-mail

Address

No. 22, Hongyuan Road, Guangzhou, Guangdong Province, China

In traditional CNC machining enterprises, the production line is mainly composed of CNC lathes, CNC machining centers, and manual operators. This configuration runs quite smoothly in scenarios where the product types are relatively single and the production scale is moderate. However, with the changing times, enterprises are facing multiple challenges such as continuously rising labor costs, tight supply in the labor market, increased labor intensity in on-site operations, and significantly increased worker mobility. These environmental factors have gradually exposed the limitations of traditional production models, which are no longer able to meet the actual production needs of current enterprises.

Industry pain points:

1. Long working hours and easy fatigue caused by manual labor

2. Inconsistent quality of manually loaded and unloaded products

3. The homework environment is complex and poses high safety risks.

Solution:

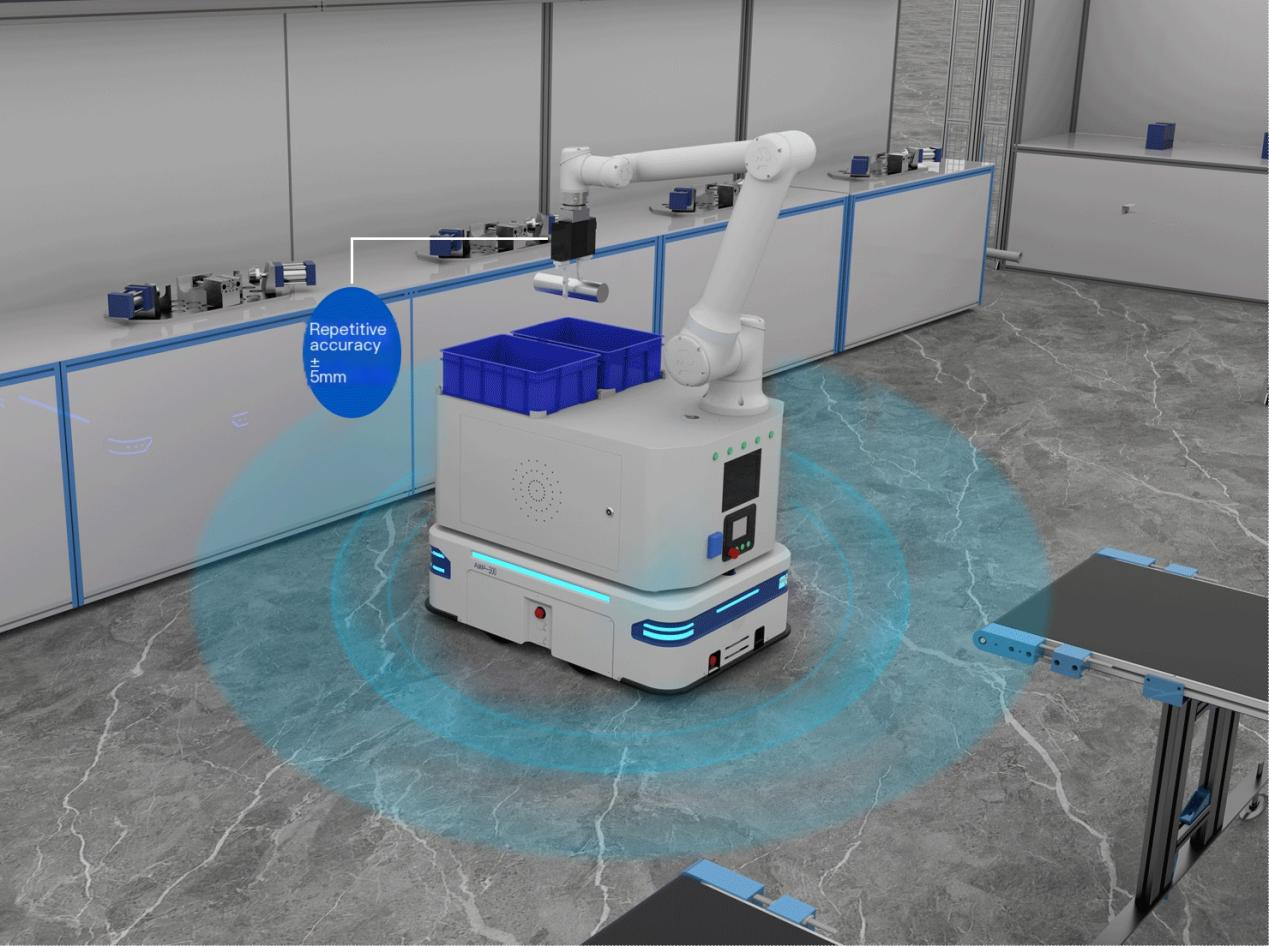

The Fuwei intelligent composite robot achieves high-precision positioning function through the use of AI+multi-sensor fusion. The 3D visual repetitive positioning accuracy is as high as 0.02mm, which can effectively identify materials and achieve efficient picking and placing with end fixtures. In addition, equipped with SLAM LiDAR and robot AI intelligent algorithm engine, combined with visual AI deep learning large model to achieve safety management, intelligent storage location management, intelligent loading and unloading, path analysis and optimization, path obstacle recognition and alarm light functions, making the robot more efficient, intelligent and safe.

No. 22, Hongyuan Road, Guangzhou, Guangdong Province, China

Copyright © 2024 Guangzhou Fuwei Electronic Technology Co., Ltd. All Rights Reserved.

Links | Sitemap | RSS | XML | Privacy Policy |