QR Code

About Us

Products

Contact Us

Phone

E-mail

Address

No. 22, Hongyuan Road, Guangzhou, Guangdong Province, China

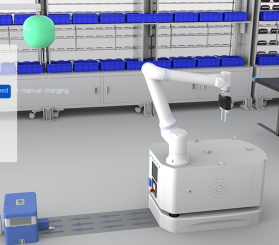

In the manufacturing industry, material handling and loading/unloading are essential links. However, traditional manual loading and unloading methods have problems such as low efficiency and high costs. In order to solve these problems, composite robot loading and unloading technology has emerged. This article will introduce the advantages and application scenarios of composite robot loading and unloading technology, helping enterprises achieve improved production efficiency and cost reduction.

1、 Advantages of Composite Robot Loading and Unloading Technology

1 Improving production efficiency: The loading and unloading technology of composite robots can achieve fast and accurate material handling and loading and unloading, greatly improving production efficiency. Compared with traditional loading and unloading methods, the automatic charging function enables the composite robot to work continuously without being affected by fatigue factors, ensuring the stability and sustainability of production.

2 Cost reduction: The use of composite robot loading and unloading technology can reduce labor costs. The traditional manual loading and unloading method requires a large amount of human resources, while composite robots can replace some of the manpower and reduce labor costs. Meanwhile, composite robots can reduce errors and damages caused by human factors, thereby lowering production costs.

3 High flexibility: The scheduling system is responsible for coordinating and managing the task allocation, path planning, and time arrangement of multiple composite robots in the production process to ensure the smooth progress of the entire production process, complete various loading and unloading tasks, and improve the flexibility of the production system.

4. Improve safety: Traditional loading and unloading methods have certain safety risks, such as accidental injuries during manual handling. Composite robots have the characteristics of high automation and intelligence, which can avoid safety accidents caused by human operation errors and improve production safety.

2、 Application scenarios of composite robot loading and unloading technology

Automotive manufacturing industry: The automotive manufacturing industry is an important field for the application of composite robot loading and unloading technology. On the automobile production line, composite robots can complete material handling and loading and unloading tasks in welding, painting, assembly and other processes, improving production efficiency.

Electronic manufacturing industry: The electronic manufacturing industry has extremely high requirements for production efficiency and accuracy. The loading and unloading technology of composite robots can complete the handling and loading and unloading of precision parts in the field of electronic manufacturing, ensuring the stability and accuracy of production.

Logistics industry: The logistics industry is another important field for the application of composite robot loading and unloading technology. In warehousing and distribution centers, composite robots can perform loading, unloading, handling, and sorting of goods, improving logistics efficiency.

Pharmaceutical industry: In the pharmaceutical industry, composite robot loading and unloading technology can be used in the production and packaging process of drugs. It can quickly and accurately complete tasks such as pill packaging, sealing, and labeling, improving production efficiency.

With the transformation and upgrading of the manufacturing industry and the acceleration of intelligent transformation, the application prospects of composite robot loading and unloading technology will be even broader. By introducing composite robot loading and unloading technology, enterprises can improve production efficiency and reduce costs, enhancing market competitiveness.

No. 22, Hongyuan Road, Guangzhou, Guangdong Province, China

Copyright © 2024 Guangzhou Fuwei Electronic Technology Co., Ltd. All Rights Reserved.

Links | Sitemap | RSS | XML | Privacy Policy |