QR Code

About Us

Products

Contact Us

Phone

E-mail

Address

No. 22, Hongyuan Road, Guangzhou, Guangdong Province, China

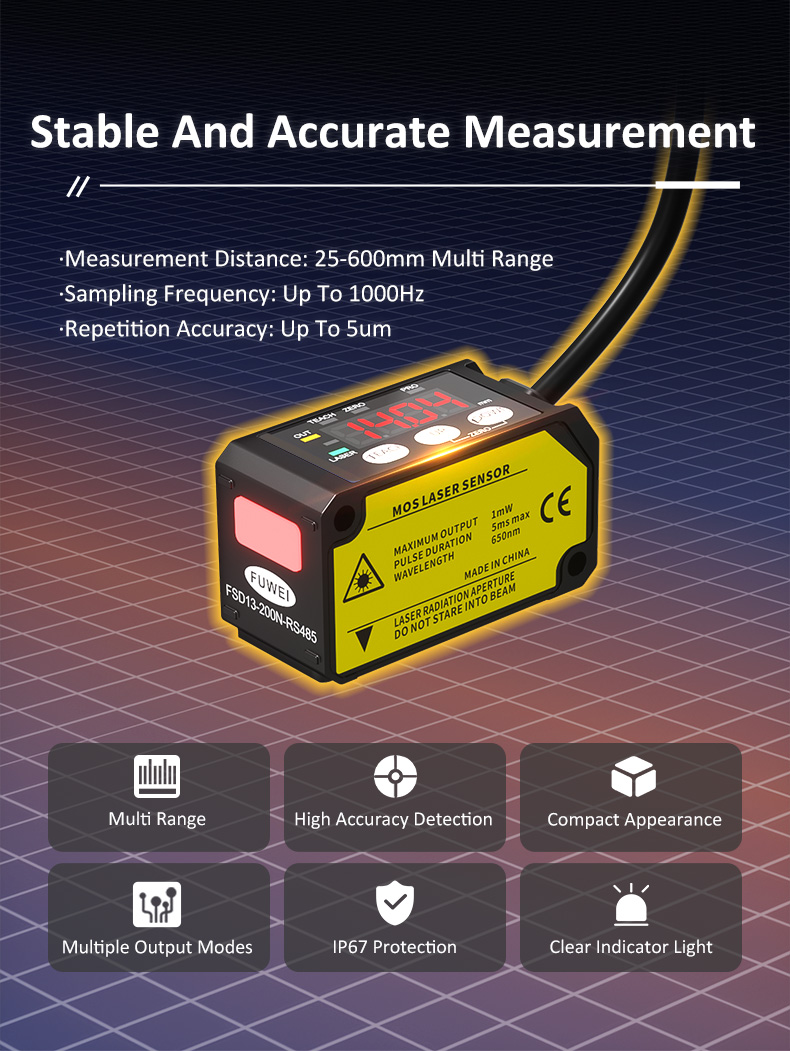

In the field of industrial automation, high-precision, high-reliability displacement measurement has always been the core guarantee of production efficiency and product quality. Fuwei Electronics' newly launched CMOS laser displacement sensor FSD13 series, with its breakthrough technical design and stringent industrial-grade standards, provides “millimeter-level precision and micrometer-level stability” intelligent detection solutions for industries such as mechanical manufacturing, electronic packaging, and food packaging, redefining measurement standards in complex operating conditions.

1. Multi-dimensional technological breakthroughs, redefining the boundaries of industrial measurement accuracy

The FSD13 series covers a wide range of measurements from 25 to 600 mm and achieves repeatability accuracy of 5 μm, enabling full-scenario adaptation from small parts to large equipment. Its 1000 Hz high-speed sampling frequency can capture minute changes in real time during dynamic processes. For example, when detecting the presence or absence of bottle cap gaskets on high-speed production lines, it can complete 0.1 mm-level precision discrimination with millisecond-level response speed.

Core technological advantages:

Unique algorithms enable precise detection

By employing adaptive filtering and edge enhancement algorithms, the FSD13 series effectively suppresses background interference, enabling stable detection of objects as small as 0.1mm. For example, in semiconductor packaging, even if the substrate surface has reflections or contaminants, the algorithm compensates to ensure curl measurement errors are less than 5μm.

Industrial-grade interference resistance

Through optimized circuit design and EMC electromagnetic compatibility certification, the sensor maintains data stability in strong electromagnetic environments (such as CNC machine tools and welding workshops), preventing misjudgments caused by signal interference.

IP67 protection for extreme conditions

Using fully automatic adhesive coating and a sealed structure design, the FSD13 series can operate normally after being submerged in 1 meter of water for 30 minutes, making it suitable for dusty and humid environments such as chemical plants and mines. For example, in roll material production lines, even when exposed to oily environments for extended periods, it can maintain roll diameter detection accuracy of ±0.1mm.

II. Full-scenario adaptability, unlocking new possibilities for smart manufacturing

The FSD13 series' modular design and multi-interface compatibility make it a “universal sensor” for industrial applications:

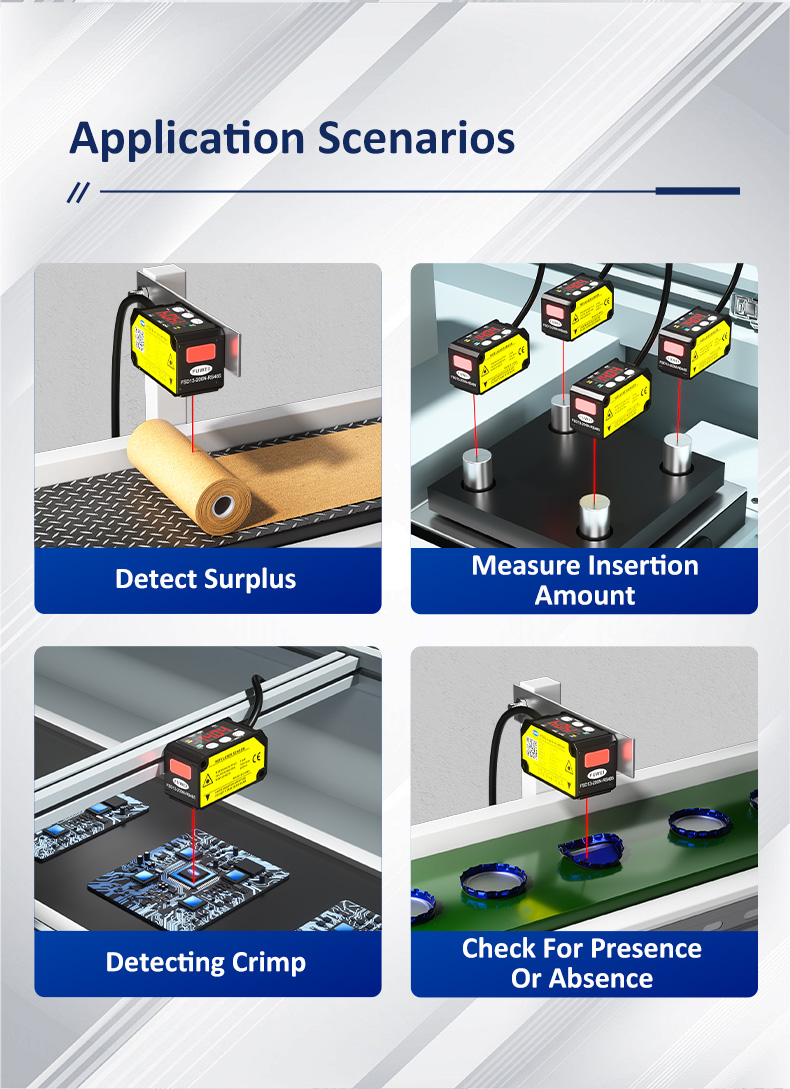

Dynamic monitoring of roll material remaining quantity

By continuously measuring changes in roll diameter and automatically calculating remaining length via algorithms, it triggers replenishment alerts in advance. In lithium-ion battery production, this feature can reduce material waste rates by over 15%.

Intelligent analysis of substrate warpage

For flexible materials such as PCB boards and semiconductor packaging substrates, the FSD13 series can generate a three-dimensional deformation map through multi-point scanning, assisting engineers in optimizing thermal pressing process parameters and controlling warpage within ±20μm.

Precision Assembly Quality Control

In automotive component assembly, sensors can monitor the insertion depth of guide pins in real time, ensuring tolerance control within ±5μm, significantly enhancing the stability of mechanical structures.

High-Speed Packaging Defect Detection

Combining a 1000Hz sampling frequency with a small spot design (minimum φ50μm), the FSD13 series achieves 100% precise detection of missing or misaligned gaskets on beverage bottle cap production lines, with a false negative rate below 0.01%.

III. Reliability Design for Long-Term Value

The FSD13 series' full lifecycle stability stems from three core designs:

Hardware-Level Durability

Featuring an aluminum alloy die-cast housing and scratch-resistant sapphire lens, it can withstand 10 million mechanical vibrations and temperature shocks ranging from -20°C to +80°C, maintaining data consistency even in extreme environments such as mines and metallurgy.

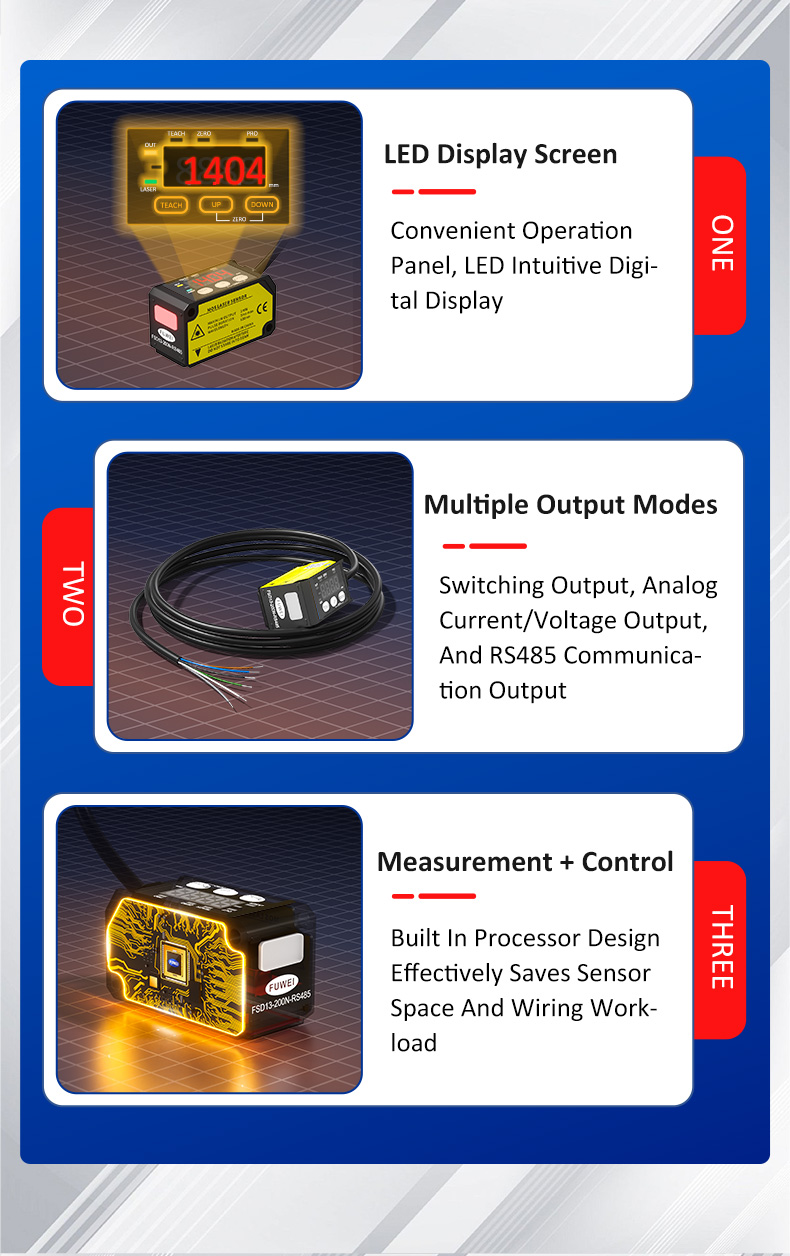

Software-Based Intelligent Maintenance

The built-in self-diagnostic system continuously monitors potential issues such as laser power decay and optical path deviation, and remotely pushes warning information via the RS485 interface, reducing downtime for maintenance by over 30%.

Multi-protocol Flexible Networking

Supports multiple output modes such as Modbus RTU, 4-20mA analog signals, and IO switch signals, enabling seamless integration with PLC and MES systems to achieve intelligent upgrades from standalone detection to production line collaboration.

IV. Benchmark Application Case: From Laboratory to Production Line

In the glass cover plate inspection line of a consumer electronics company, the FSD13 series achieved both quality and efficiency improvements through the following solution:

Inspection Challenge: The curvature of 0.3mm ultra-thin glass must be controlled within ±50μm, and traditional contact-based measurement methods can easily cause product damage.

No. 22, Hongyuan Road, Guangzhou, Guangdong Province, China

Copyright © 2024 Guangzhou Fuwei Electronic Technology Co., Ltd. All Rights Reserved.

Links | Sitemap | RSS | XML | Privacy Policy |