QR Code

About Us

Products

Contact Us

Phone

E-mail

Address

No. 22, Hongyuan Road, Guangzhou, Guangdong Province, China

In industrial automation, label detection remains a critical step in process optimization. Traditional photoelectric sensors often fail when encountering special materials like transparent films, highly reflective foil labels, or deep black substrates—due to ambient light interference or material transparency issues. Is there a technology that can completely overcome these limitations? Fuwei Electronics' ultrasonic label sensor FGU03-C delivers a definitive answer with its revolutionary ultrasonic technology.

I. Why Do Traditional Sensors Struggle with Complex Label Scenarios?

Conventional optical sensors rely on light reflection principles. When encountering mirror-like reflective labels, intense reflections cause signal overload; while detecting transparent labels, excessive light transmission prevents response triggering. More critically, on high-speed production lines, metallic labels like foil stamping cause misjudgments due to light scattering, while dark labels remain difficult to identify because of their light-absorbing properties. These pain points directly impact production yield and equipment utilization rates.

II. How Does the Ultrasonic Label Sensor Achieve a Technological Breakthrough?

The FGU03-C employs powerful ultrasonic technology, emitting high-frequency sound waves and analyzing signal attenuation to identify targets. This physical characteristic delivers three breakthrough advantages:

Absolute Immunity to Light Interference

Ultrasonic detection remains unaffected by ambient light. Whether in brightly lit workshops or on special surfaces like mirror reflections or Daming materials, the sensor maintains stable detection. This eliminates false signals caused by metallic reflections when detecting hot foil stamping labels.

Penetration Adaptability

By intelligently analyzing signal attenuation curves, the FGU03-C accurately distinguishes labels from substrate materials. It reliably identifies labels through acoustic impedance differences—even in challenging scenarios like transparent PET film labels or translucent silicone labels where traditional optical sensors struggle.

Intelligent Pattern Recognition Algorithm

The advanced algorithm embedded in this ultrasonic label sensor intelligently distinguishes label patterns from substrates based on signal characteristics. Whether labels are deep black, fully transparent, or feature color printing, the sensor focuses solely on acoustic variations caused by material density differences—truly achieving “adaptability to infinite variations.”

III. Dual Innovation in Operational Experience and Performance Metrics

Beyond exceptional detection capabilities, the FGU03-C impresses with its user-friendly design:

Ultra-fast 250-microsecond response: Meets real-time control demands of high-speed production lines

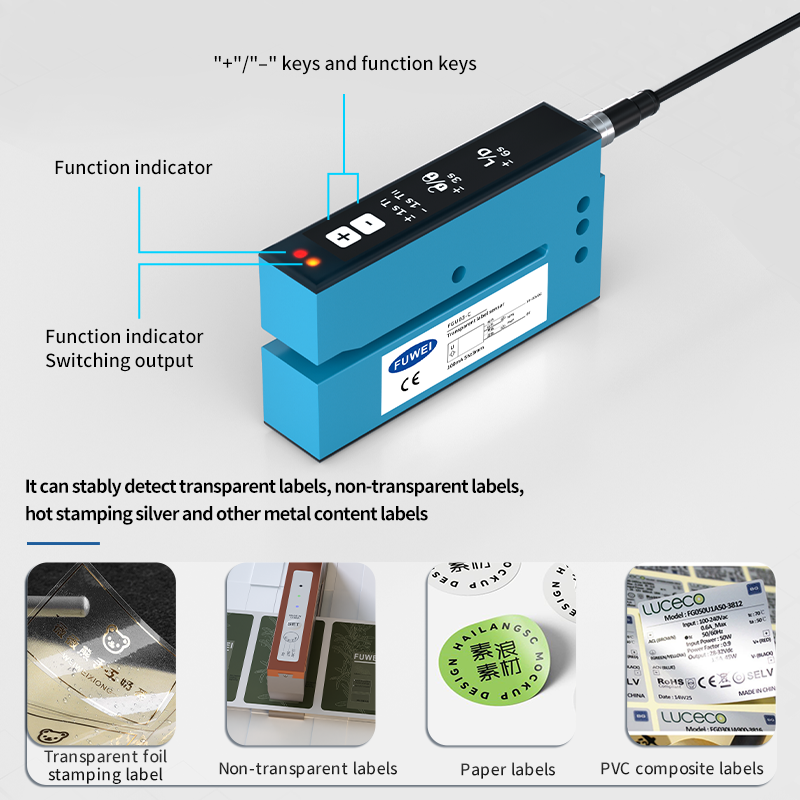

One-touch dynamic teaching: Quickly sets thresholds via plus/minus buttons—no professional debugging required

Wide-range sensitivity adjustment: Adapts to applications spanning ultra-thin labels to heavy materials

A packaging equipment manufacturer reported after using the FGU03-C ultrasonic label sensor: When detecting printed labels on transparent cling film, misjudgment rates dropped from 15% to 0.02%. On high-speed labeling machines handling hot foil labels, avoiding frequent optical adjustments boosted overall equipment efficiency by 31%.

While the industry continues to grapple with detection challenges for specialty label materials, Fuwei Electronics' FGU03-C ultrasonic label sensor delivers a mature, reliable solution. Its breakthrough non-optical detection principle not only resolves detection difficulties for transparent, reflective, and dark-colored labels but also significantly lowers the usage threshold through intelligent design. The launch of this ultrasonic label sensor marks the official entry of industrial sensing technology into a new era of “universal material compatibility.”

No. 22, Hongyuan Road, Guangzhou, Guangdong Province, China

Copyright © 2024 Guangzhou Fuwei Electronic Technology Co., Ltd. All Rights Reserved.

Links | Sitemap | RSS | XML | Privacy Policy |