QR Code

About Us

Products

Contact Us

Phone

E-mail

Address

No. 22, Hongyuan Road, Guangzhou, Guangdong Province, China

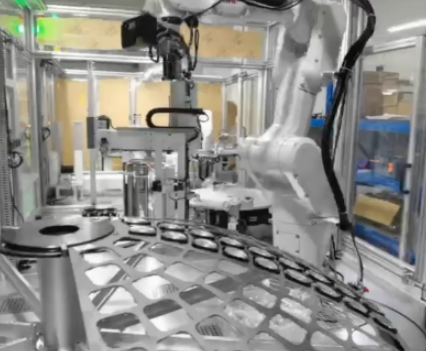

In the field of optical manufacturing, lens coating is a crucial process that directly affects the optical performance and usability of the product. However, in the traditional lens coating process, the loading and unloading operations have always relied on manual labor, which is not only inefficient, but also prone to lens damage and secondary pollution. With the continuous advancement of technology, automatic loading and unloading technology for lens coating has emerged, bringing revolutionary changes to the field of optical manufacturing.

The advantages of automatic loading and unloading technology for lens coating are significant. Firstly, it greatly improves production efficiency. The automatic loading and unloading system can quickly and accurately move and position the lenses, without the need for manual intervention throughout the entire process.

Secondly, the automatic loading and unloading technology for lens coating ensures product quality through precise positioning and robotic arm operation.

Furthermore, with the gradual increase in labor costs and the increasing shortage of human resources, automatic loading and unloading systems have become an ideal choice for enterprises. It can replace some manual operations, reduce labor costs and manpower input, and save considerable expenses for enterprises.

No. 22, Hongyuan Road, Guangzhou, Guangdong Province, China

Copyright © 2024 Guangzhou Fuwei Electronic Technology Co., Ltd. All Rights Reserved.

Links | Sitemap | RSS | XML | Privacy Policy |