QR Code

About Us

Products

Contact Us

Phone

E-mail

Address

No. 22, Hongyuan Road, Guangzhou, Guangdong Province, China

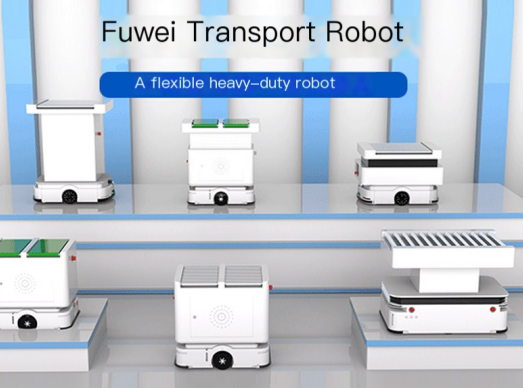

In today's fast-paced industrial production environment, efficiency and safety have become important components of a company's core competitiveness. As a new generation of intelligent handling solution, Fuwei mobile robots, with their excellent performance and intelligent technology, have equipped the lithium battery industry with a powerful "handling wing" for efficient handling.

Fuwei mobile robots not only solve the problems of low efficiency and multiple safety hazards in traditional handling methods, but also greatly reduce the risk of accidents with their highly automated operations and powerful data processing capabilities, while improving handling efficiency.

Users are the leading enterprises in the industry, always adhering to the principle of market orientation, constantly strengthening technological innovation, and committed to promoting enterprises to reach higher heights.

Industry pain points:

In the user's production workshop, material transportation and loading/unloading mainly rely on manual operations. Due to the particularity of the industry, there are extremely high requirements for the precision of mobile robots in order to save human resources to the greatest extent possible. Meanwhile, in the user's on-site environment, there are complex situations such as high-frequency material handling, mixed flow of people and vehicles, narrow space, and frequent passage through air shower doors and elevators.

Solution

The use of Fuwei mobile robots, composite robots, and transport robots can achieve cross map traffic management and efficient collaborative operations.

Several Fuwei transfer robots are deployed in the interval from the roller cutting process to the small coil polarizer buffer process to achieve autonomous handling and reflow. These robots need to autonomously dock with machines in narrow channel spaces to complete loading and unloading operations with an accuracy of up to ± 0.2mm. At the same time, they can also autonomously pass through more than ten air shower doors and rolling shutter doors on site, freely enter and exit elevators, and complete material transportation tasks.

In the coating and slitting section area, several Fuwei intelligent composite robots have been deployed to solve industry problems such as high load, high precision requirements, and the need for manual assistance in the loading and unloading scenarios of extreme rolls. These robots are capable of achieving automated loading and unloading of polar rolls and logistics transportation, greatly improving production efficiency. Multiple safety measures ensure the normal operation of the composite robot in narrow passages, guaranteeing the safety of production.

Program value:

Helping users achieve cost reduction and efficiency improvement, the application of mobile robots can meet the high-frequency material turnover needs and improve production line efficiency.

By introducing Fuwei mobile robots, the lithium battery industry has achieved a transformation from traditional manual labor to intelligent automation in material transportation and loading and unloading. This not only greatly improves the efficiency of handling and reduces labor costs, but also effectively solves the challenges brought by complex situations such as mixed traffic and narrow space. Fuwei mobile robots, with their excellent performance and intelligent technology, have equipped the lithium battery industry with a powerful "handling wing" for efficient production. In the future, with the continuous advancement of technology, we have reason to believe that Fuwei mobile robots will unleash their enormous potential in more fields, driving the entire industrial production into a new stage of development.

No. 22, Hongyuan Road, Guangzhou, Guangdong Province, China

Copyright © 2024 Guangzhou Fuwei Electronic Technology Co., Ltd. All Rights Reserved.

Links | Sitemap | RSS | XML | Privacy Policy |