QR Code

About Us

Products

Contact Us

Phone

E-mail

Address

No. 22, Hongyuan Road, Guangzhou, Guangdong Province, China

In the modern automotive manufacturing industry, the feeding process of door inner panels is crucial for production efficiency and product quality. In order to improve the automation level of the production line, reduce manual intervention, and ensure the accuracy and efficiency of feeding, we propose a solution of visually guiding the feeding of car door inner panels.

Customer pain points:

Stamped workpieces have characteristics such as a wide variety of types, large size differences, and complex structures. There are still problems in production such as high precision requirements, fast addition of vehicle models, and high tooling maintenance costs, which make it difficult for manual or robot fixed trajectory grasping and feeding methods to meet the actual production needs of automobiles.

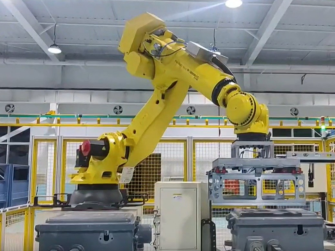

Fuwei Intelligence, with its outstanding technological strength, has successfully assisted numerous automotive OEMs and component factories in achieving flexible automation. Taking a well-known large automotive parts factory as an example, the factory has adopted an innovative solution provided by Fuwei Intelligence in the feeding process of the car door inner panel, integrating AI, 3D vision, and industrial robot technology. Since the introduction of this plan and its implementation in production, the production quality and efficiency of the production line have significantly improved. Specifically, the single line production capacity has achieved a growth of more than twice, truly realizing the goal of fully automated production.

Project Overview

The enterprise needs to process a large number of car door inner panels every day, involving complex processing procedures. In the original production method, workers were responsible for transporting the inner panels from the material rack to the laser room welding fixture, and after completing laser welding, they were manually transported to the next workstation. However, with the increasing scale of production, the traditional manual operation mode has gradually exposed limitations in quality and efficiency, making it difficult to meet the growing production needs of enterprises.

Project highlights

01The application of precise recognition and grasping technology has significantly improved the production quality of car door inner panels

In this project, we used a high-precision 3D vision system specifically for taking photos of the precision machined main and auxiliary positioning pin holes on the car door inner panel. The system ensures the accuracy of the pin grabbing process by capturing precise information about the position of the pin hole. Due to the small diameter of the pinhole and the presence of reflection on the surface of the workpiece, this places extremely high demands on the recognition ability of the 3D vision system.

The application of 3D cameras can accurately capture the detailed features of small aperture pin holes on the car door inner panel, generate complete, accurate, and detailed point cloud data, and provide a solid data foundation for subsequent automation processing.

The Fuwei intelligent 3D vision system can guide robots to accurately grasp, avoiding deformation and damage to the door inner panel caused by squeezing and scratching, and improving the production quality of the door inner panel.

02High flexibility, helping customers reduce costs and increase efficiency

At the project site, due to the existence of four different types of door inner panels in the same batch, including left front door, right front door, left middle door, and right middle door, each type of inner panel is stored on a specific rack. Due to the differences in the positions of these different types of inner plate pin holes, it poses corresponding challenges to the adaptability and flexibility of our 3D vision system. Our 3D vision system needs to be able to accurately recognize the features of different inner panels and flexibly adjust the recognition parameters to ensure accurate capture of pin hole position information for various types of inner panels.

03Efficient and stable, better achieving seamless integration throughout the entire production process

The planning and layout of automobile production workshops not only need to consider various aspects such as accuracy assurance, production efficiency, and distribution logistics, but also need to take into account existing conditions such as factory environment and workstation layout. Realizing efficient and stable production, and better connecting various production processes are also issues of particular concern to automobile manufacturers. The Fuwei Intelligent 3D Vision System has the following advantages:

The 3D vision system accurately locates two pin holes, effectively guiding the robot to efficiently grasp and significantly improving the operational efficiency of the production line. In addition, Fuwei Intelligent's independently developed intelligent collision detection and trajectory planning algorithm can intelligently select the optimal robot motion path and entry angle, effectively avoiding collisions that may be caused by material rack interference, preventing inner plate deformation, and further ensuring the stability of the production process and product quality.

Fuwei Intelligent's 3D vision products have excellent environmental adaptability, and can achieve high-quality imaging of various objects even under complex and changing environmental light interference. At the same time, it can maintain long-term stable operation in harsh environments such as dust, vibration, humidity, electromagnetic interference, and high temperature, providing reliable technical support for automated production in the automotive manufacturing industry.

The Fuwei intelligent 3D vision system can guide robots to accurately grasp, with many advantages such as high production efficiency, high stability, and quick adaptation to product changes. It can effectively meet the requirements of many car companies for high efficiency, high qu

No. 22, Hongyuan Road, Guangzhou, Guangdong Province, China

Copyright © 2024 Guangzhou Fuwei Electronic Technology Co., Ltd. All Rights Reserved.

Links | Sitemap | RSS | XML | Privacy Policy |