QR Code

About Us

Products

Contact Us

Phone

E-mail

Address

No. 22, Hongyuan Road, Guangzhou, Guangdong Province, China

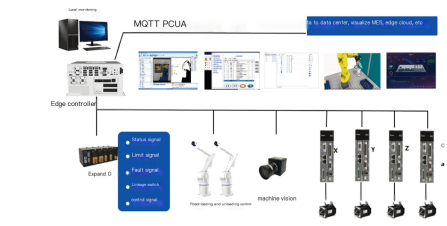

In today's increasingly complex and ever-changing industrial manufacturing environment, traditional assembly lines face multiple challenges such as redundant multi-layer controller architectures, increased flexibility requirements, diverse controller languages, and low standardization levels. To address these industry pain points, Fuwei Intelligent has successfully built a reconfigurable flexible assembly production line with its innovative AI-ICDP platform, bringing unprecedented changes to industrial manufacturing.

Traditional assembly lines are usually composed of various controllers such as industrial computers and PLCs. This multi-layer architecture is not only bulky and cost-effective, but also has limited computing power in the control layer, making it difficult to meet the needs of big data processing. However, Fuwei Intelligent's reconfigurable flexible assembly production line adopts an efficient AI edge controller to achieve precise control of the entire system. This innovative design not only simplifies the system architecture and improves cost-effectiveness, but also significantly enhances data processing capabilities, providing strong support for CNC automation assembly of cross category products.

In the era of personalized products, frequent changes in assembly products require increasingly high flexibility in production lines. Fuwei Intelligent's reconfigurable flexible assembly production line achieves rapid reconfiguration of the assembly environment through the use of flexible manufacturing units and intelligent control software. This means that no matter how the product changes, the production line can be quickly adjusted to ensure a smooth and efficient assembly process. This flexible design not only reduces quality fluctuations caused by manual assembly, but also lowers production line replacement cycles and costs, improving overall efficiency.

In addition, traditional automation equipment usually requires the participation of multiple personnel such as upper and lower machine development, and software deployment and programming work are cumbersome and require high personnel requirements. Fuwei Intelligent's reconfigurable flexible assembly production line adopts a unified control platform, simplifying software deployment and programming work, and reducing personnel requirements. This makes the production line easier to operate and maintain, reducing usage costs.

It is worth mentioning that Fuwei Intelligent's reconfigurable flexible assembly production line also has a high degree of standardization. Due to the use of a unified control platform and assembly unit, the differences between equipment are greatly reduced, and the labor costs for debugging and use are correspondingly reduced. This not only improves the stability and reliability of the production line, but also provides strong support for the scale production and expansion of enterprises.

Fuwei Intelligent's reconfigurable flexible assembly production line based on AI-ICDP has brought revolutionary changes to industrial manufacturing with its efficient control capabilities, powerful flexible design, simplified operation processes, and high degree of standardization. This innovative solution will strongly promote the development of industrial manufacturing towards a more intelligent and efficient direction, laying a solid foundation for realizing a truly intelligent factory.

No. 22, Hongyuan Road, Guangzhou, Guangdong Province, China

Copyright © 2024 Guangzhou Fuwei Electronic Technology Co., Ltd. All Rights Reserved.

Links | Sitemap | RSS | XML | Privacy Policy |