QR Code

About Us

Products

Contact Us

Phone

E-mail

Address

No. 22, Hongyuan Road, Guangzhou, Guangdong Province, China

In industrial automation, precise detection and rapid response are key to boosting production efficiency. As an operator at Fuwei Electronics, I'm excited to introduce a revolutionary product today—the RGB Digital Color Mark Sensor FGS-31N. This sensor not only integrates advanced RGB technology but also achieves outstanding performance through digital processing, finding widespread application in industries like packaging and metal processing. So, how does it strike the perfect balance between high speed and high precision? This article will delve into the core features of this RGB digital color mark sensor and demonstrate how it addresses industry pain points through real-world applications. The keyword “RGB digital color mark sensor” will be central throughout, helping you gain a comprehensive understanding of this innovative tool.

First, let's examine the fundamental specifications of the FGS-31N RGB digital color mark sensor. Its measurement range spans 7–13mm, with a spot size of approximately 1×5mm (at a 10mm distance). This compact design ensures precise positioning in confined spaces. The optimized spot size allows the sensor to focus on small target areas, minimizing false detections, while its flexible measurement range adapts to diverse industrial environments. Whether on high-speed production lines or for complex pattern detection, this RGB digital color mark sensor delivers stable performance. Through digital processing technology, it analyzes reflected light data in real time, ensuring highly reliable detection results.

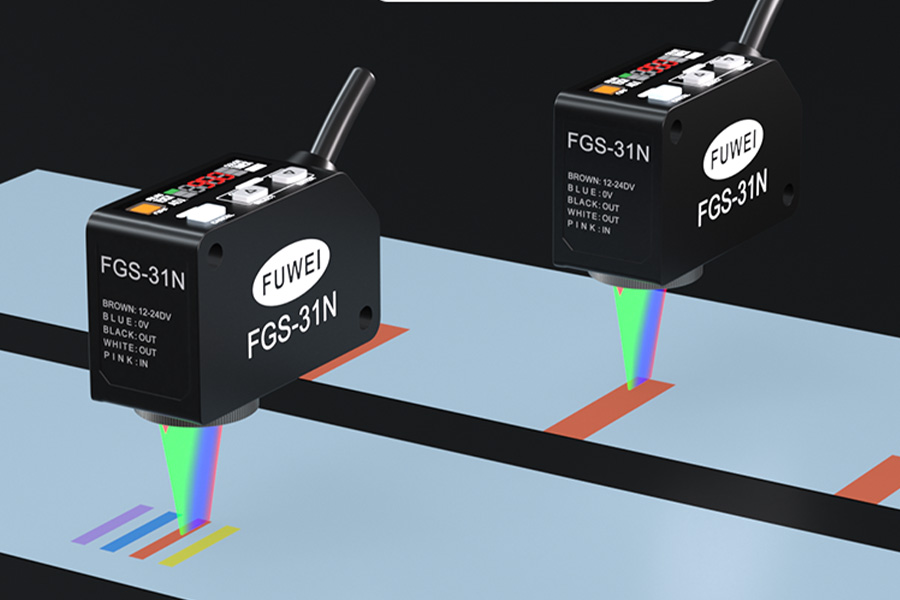

Next, we focus on the sensor's two detection modes: Color Mark Mode and Color Mode. These modes can be flexibly selected based on actual applications, fully demonstrating the product's intelligent design. In Color Mark Mode, the sensor automatically selects a single monochromatic light from its three LEDs (R·G·B) for detection, achieving an ultra-fast response time of up to 45μs. This mode leverages an optimal LED auto-selection function to intelligently identify the most suitable LED light source for detection, enabling precise capture of color mark changes during high-speed motion. For instance, in detecting color marks on packaging tape, production lines often operate at extreme speeds. Traditional sensors may misjudge due to response delays, but the FGS-31N's Color Mark Mode ensures zero errors, significantly boosting efficiency. This highlights the unique advantage of the RGB Digital Color Mark Sensor in high-speed applications—it not only shortens detection time but also optimizes signal processing through digital algorithms, minimizing environmental interference.

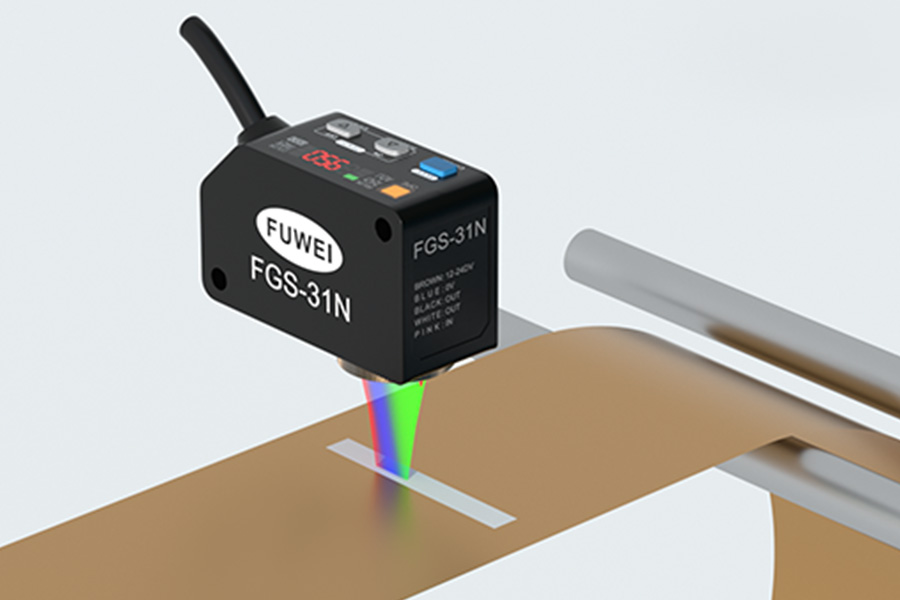

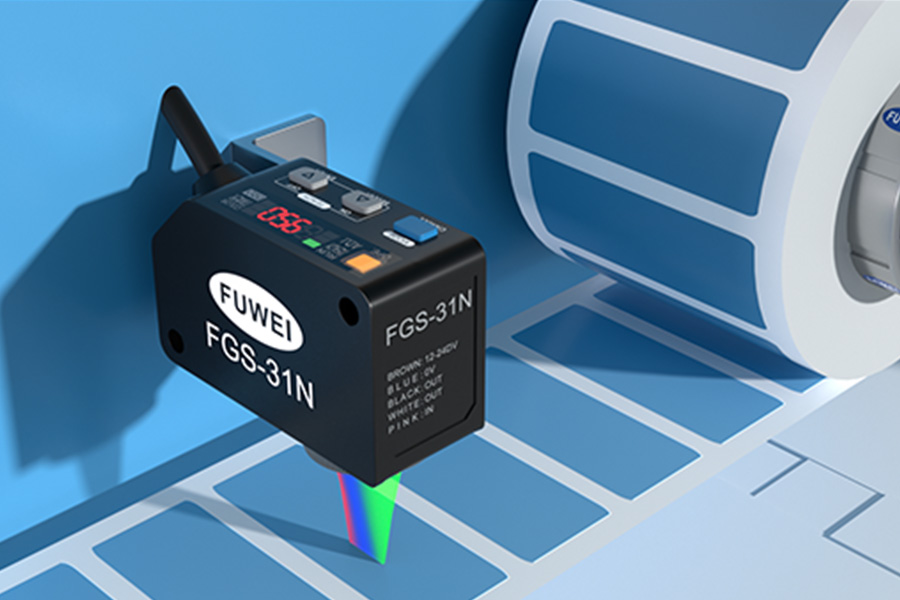

In color mode, the RGB digital color mark sensor simultaneously utilizes R, G, and B LED light sources. By analyzing the RGB ratio of reflected light, it achieves high-precision color discrimination. This mode is particularly suitable for complex scenarios, such as detecting color marks on films with surrounding patterns or designs. For instance, when inspecting adhesive tape affixed to metallic copper foil, the tape's color may resemble the background. Yet the sensor accurately distinguishes the target by detecting subtle differences in RGB ratios, preventing missed or false detections. This high-precision capability enables the RGB digital color mark sensor to excel in dynamic production environments. It not only enhances detection accuracy but also expands application scope, meeting modern industry demands for intelligence and diversity.

In practical applications, the RGB digital color mark sensor FGS-31N demonstrates exceptional performance. For instance, in detecting color marks on packaging machine material strips, production lines often require rapid identification of mark positions to control cutting or sorting. The FGS-31N's color mark mode achieves a 45μs response time, ensuring seamless operation during high-speed production. Simultaneously, in detecting adhesive tape applied to metallic copper foil, the color mode leverages RGB analysis to effectively overcome challenges posed by metallic reflections and pattern interference, enhancing detection reliability. These scenarios fully demonstrate the multifunctionality of the RGB digital color mark sensor—it is not only a powerful tool for high-speed detection but also an expert in high-precision identification. By integrating digital processing technology, the sensor adapts to environmental changes, reduces maintenance costs, and saves enterprises time and resources.

Overall, the FGS-31N RGB digital color mark sensor stands as an ideal choice for industrial automation with its exceptional measurement range, flexible spot design, and efficient detection modes. Whether in the speed-driven packaging industry or precision-focused metal processing, it delivers reliable solutions. As a core product of Fuwei Electronics, we are confident this RGB digital color mark sensor will help you boost production efficiency and reduce operational costs.

No. 22, Hongyuan Road, Guangzhou, Guangdong Province, China

Copyright © 2024 Guangzhou Fuwei Electronic Technology Co., Ltd. All Rights Reserved.

Links | Sitemap | RSS | XML | Privacy Policy |