QR Code

About Us

Products

Contact Us

Phone

E-mail

Address

No. 22, Hongyuan Road, Guangzhou, Guangdong Province, China

The combination of composite robots and 2D vision technology has brought revolutionary changes to the chip manufacturing industry in the pursuit of efficient and precise manufacturing processes. This technology can achieve high-precision positioning and grabbing of chip material frames, greatly improving production efficiency and quality stability.

Chips, seemingly tiny components, play an indispensable role in various industries. In the field of electronic manufacturing, it is the heart of electronic products, making information transmission and processing possible. In the communication industry, chips provide technical support for the high-speed flow of global information. In automobile manufacturing, it has improved the performance and safety of vehicles, promoting the development of intelligent transportation. Therefore, the importance of chips is self-evident, and traditional manual handling is difficult and risky. How to use artificial intelligence technology to replace manual work is an urgent problem that enterprises need to solve.

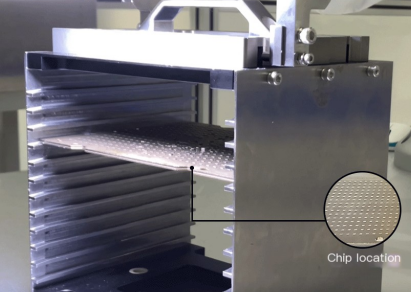

2D vision guided composite robot for high-precision positioning and grabbing of chip material frames

Case background

Chips have the characteristics of being small, thin, and easily damaged, and traditional manual operations are no longer able to meet the requirements of high precision, high efficiency, and high reliability. Meanwhile, in the process of electronic manufacturing, the positioning and grasping of chip material frames are crucial links, and their accuracy and stability directly affect the quality and production efficiency of products. For this application scenario, Fuwei Intelligent can easily meet the needs of this application by using composite robots combined with 2D machine vision.

Technical difficulties:

How to ensure that small chips do not fall off during grabbing;

How to ensure that robots can still travel stably on uneven ground.

Solution

The composite robot uses a high-resolution 2D camera to obtain the image position of the chip material frame, and then preprocesses, extracts features, and matches the image through image processing algorithms to achieve precise positioning of the chip material frame. In order to improve positioning accuracy, we adopted advanced machine learning algorithms for deep learning and feature extraction of images, thereby more accurately identifying the position and orientation of chip material frames.

Project Value:

1. Improving production efficiency: By using composite robot 2D vision high-precision positioning and grabbing technology for chip material frames, fast, accurate, and stable positioning and grabbing can be achieved, greatly improving production efficiency, shortening production cycles, and accelerating product launch time.

2. Improving product quality: High precision positioning technology can ensure accurate alignment of chip material frames, reduce errors caused by human factors, and lower the rate of chip damage.

3. Reduce labor costs: The use of automated and intelligent composite robot technology can replace human labor and reduce labor costs. Meanwhile, precise positioning and efficient grasping can reduce material loss and waste, further lowering production costs.

4. Enhance flexible production capacity: Composite robot technology can adapt to chip material frames of different shapes, sizes, and positions, quickly switch production, meet the production needs of multiple varieties and small batches, and enhance the flexible production of enterprises.

The AI+2D visual guidance solution technology of Fuwei Intelligence for workpiece loading and unloading is already very mature, with strong usability, which can significantly improve the accuracy and efficiency of workpiece loading, further enhancing the automation and flexibility level of customers' production lines. In order to meet the actual needs of customers, Fuwei Intelligence will continue to provide efficient and flexible AI+2D visual solutions, providing strong support for the intelligent transformation and development of enterprises.

No. 22, Hongyuan Road, Guangzhou, Guangdong Province, China

Copyright © 2024 Guangzhou Fuwei Electronic Technology Co., Ltd. All Rights Reserved.

Links | Sitemap | RSS | XML | Privacy Policy |