QR Code

About Us

Products

Contact Us

Phone

E-mail

Address

No. 22, Hongyuan Road, Guangzhou, Guangdong Province, China

In the field of industrial detection, a sensor that can adapt to complex environments and stably output detection results is often the key to improving production efficiency. The FGNH09-SA801N miniature photoelectric sensor stands out among similar products with its core advantages such as all-material detection capability, ultra-long service life, and clear status indication. What unique features does it have to meet diverse detection needs?

Breaking Material Limitations for Precise Detection in All Scenarios

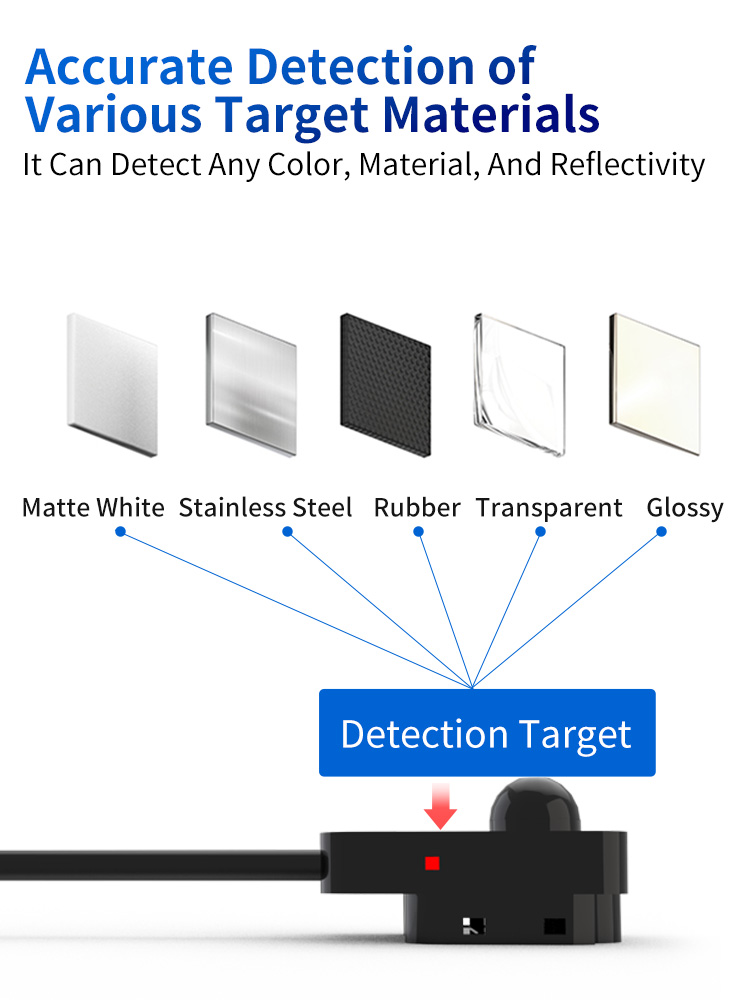

Traditional photoelectric sensors are often affected by the target's color, material, or reflectivity, and are prone to misjudgment when detecting dark objects, transparent materials, or low-reflectivity surfaces. The FGNH09-SA801N completely breaks this limitation—it can accurately identify detection objects regardless of their material (such as metal, plastic, glass, fabric, etc.), color (black, white, red, etc.), or even surfaces with extremely low reflectivity like matte finishes.

This all-material detection capability stems from its optimized optical system design: a high-precision infrared emitting tube works with a high-sensitivity receiving device, which can effectively filter out ambient light interference. Even in strong or dim light environments, it can stably capture target signals. In the electronics manufacturing industry, it can accurately detect black insulating layers and silver solder joints on circuit boards; in food packaging lines, it can easily identify dark ingredients wrapped in transparent plastic films; in logistics sorting scenarios, it can achieve undifferentiated detection of packages of different colors and materials, greatly reducing the rates of missed and misdetections caused by material differences.

Ultra-Long Mechanical Lifespan, Reducing Long-Term Usage Costs

The service life of industrial equipment directly affects production continuity and maintenance costs. The FGNH09-SA801N has a mechanical lifespan of over 5 million operations, far exceeding the industry average. This figure means that if the equipment runs for 10 hours a day with an interval of 1 second between each detection operation, it can work continuously and stably for nearly 17 years, significantly reducing the frequency of sensor replacement.

The secret to its ultra-long lifespan lies in the precision manufacturing of core components: the interior uses wear-resistant alloy contacts and high-elasticity springs to ensure the stability and consistency of each mechanical action; the sealed structure design effectively isolates dust and moisture, allowing it to maintain good performance even in dusty workshops or humid environments. For manufacturing enterprises, this not only reduces the time cost of shutting down to replace sensors but also lowers long-term procurement and maintenance expenses, making it particularly suitable for the long-term operation needs of large-scale automated production lines.

Multi-Side LED Indicators for Clear Status Monitoring

In a busy production site, whether the working status of the sensor is clearly visible directly affects the judgment efficiency of operators. The FGNH09-SA801N innovatively features 3-side LED action indicators: 2 on the sides and 2 on the top, totaling 4 red LED beads. This layout allows operators to clearly see the on/off status of the indicators from the front, side, or top of the equipment, and keep track of the sensor's working condition in real-time.

The red LED beads have high brightness and strong penetration, making them not easily overlooked even in strong or backlit workshop environments. When the sensor detects a target, the indicator lights up synchronously, allowing operators to quickly judge whether the detection is normal; if a fault occurs, the flicker frequency of the indicator changes, which can promptly remind maintenance personnel to troubleshoot. This intuitive status feedback mechanism is particularly important in high-precision scenarios such as semiconductor wafer carrier (FOUP) detection, as it can avoid production errors caused by misjudgment of status.

turdy Mounting Bracket for Complex Industrial Environments

The installation stability of the sensor is the basis for ensuring detection accuracy. The FGNH09-SA801N is equipped with an M3 steel mounting bracket, made of high-strength stainless steel, which has excellent corrosion and vibration resistance. The surface of the bracket has undergone anti-rust treatment, enabling it to maintain structural stability for a long time even in high-temperature, high-humidity, or chemically corrosive environments, avoiding sensor position deviation caused by bracket deformation that affects detection accuracy.In addition, the bracket design takes into account installation flexibility—through the M3 threaded interface, it can be adapted to various industrial guide rails and fixing bases to meet the installation needs of different equipment.

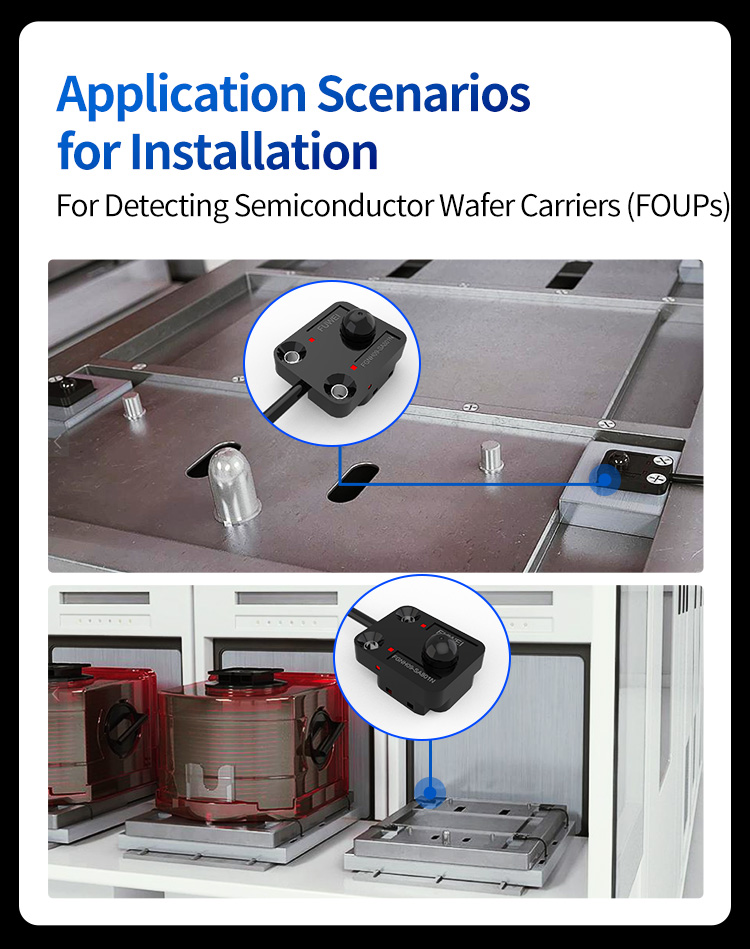

Whether inside compact semiconductor equipment or beside open production lines, it can be fixed quickly, shortening equipment debugging time.Focusing on the Semiconductor Field for More Reliable FOUP DetectionIn semiconductor manufacturing, the detection of the presence of wafer carriers (FOUPs) is a key link in ensuring the safety of wafer transportation. The button-type design of the FGNH09-SA801N is perfectly suited for FOUP detection scenarios: its compact size can be embedded in the narrow space of equipment to accurately detect whether the FOUP is in place; its all-material detection capability ensures stable response to different parts of the FOUP such as plastic shells and metal buckles; and its ultra-long lifespan and high stability meet the strict requirements of high cleanliness and high continuous operation in semiconductor workshops.

In addition to the semiconductor field, this sensor is also widely used in electronic assembly, automobile manufacturing, logistics sorting, and other scenarios, serving as a "reliable eye" connecting automated equipment and detection targets.From the flexibility of all-material detection to the economy of ultra-long lifespan, from clear status indication to sturdy installation design, the FGNH09-SA801N miniature photoelectric sensor provides an efficient solution for industrial detection with comprehensive advantages. For enterprises pursuing high precision and low maintenance costs, it is not only a detection tool but also a powerful assistant for improving production efficiency.

No. 22, Hongyuan Road, Guangzhou, Guangdong Province, China

Copyright © 2024 Guangzhou Fuwei Electronic Technology Co., Ltd. All Rights Reserved.

Links | Sitemap | RSS | XML | Privacy Policy |