QR Code

About Us

Products

Contact Us

Phone

E-mail

Address

No. 22, Hongyuan Road, Guangzhou, Guangdong Province, China

In the precision-driven realm of industrial automation, the millimeter-level positioning of robotic arms and the micrometer-level identification of bottle cap gaskets all rely on reliable detection equipment. As the “sharp-eyed” component of industrial measurement and control systems, the performance of laser displacement sensors directly determines the upper limit of production precision. The FSD11 laser displacement sensor, optimized for specific application scenarios, has become an indispensable tool for robotic arm positioning and packaging inspection, redefining the application standards for laser displacement sensors in niche scenarios.

Scene Adaptability: Versatile Performance from Millimeter Positioning to Micron Detection

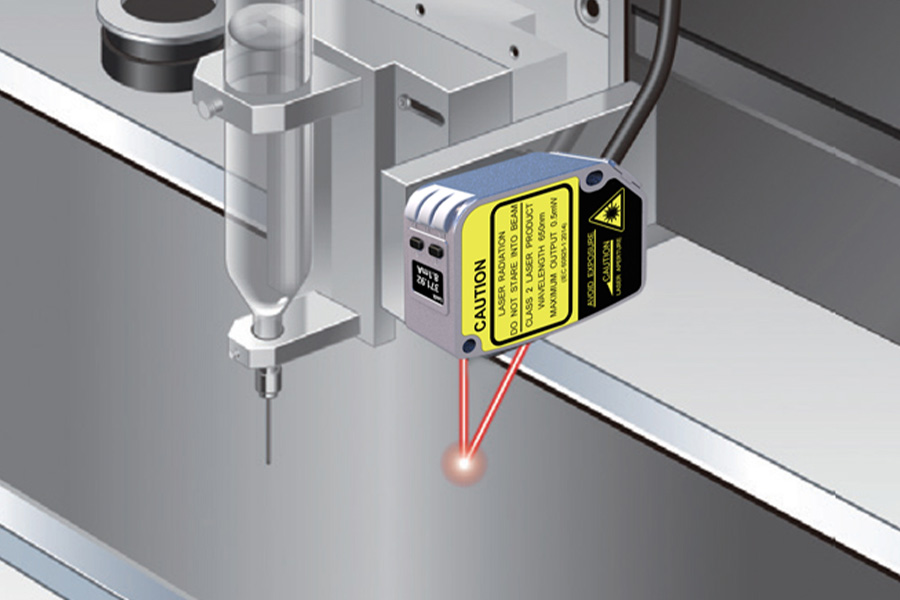

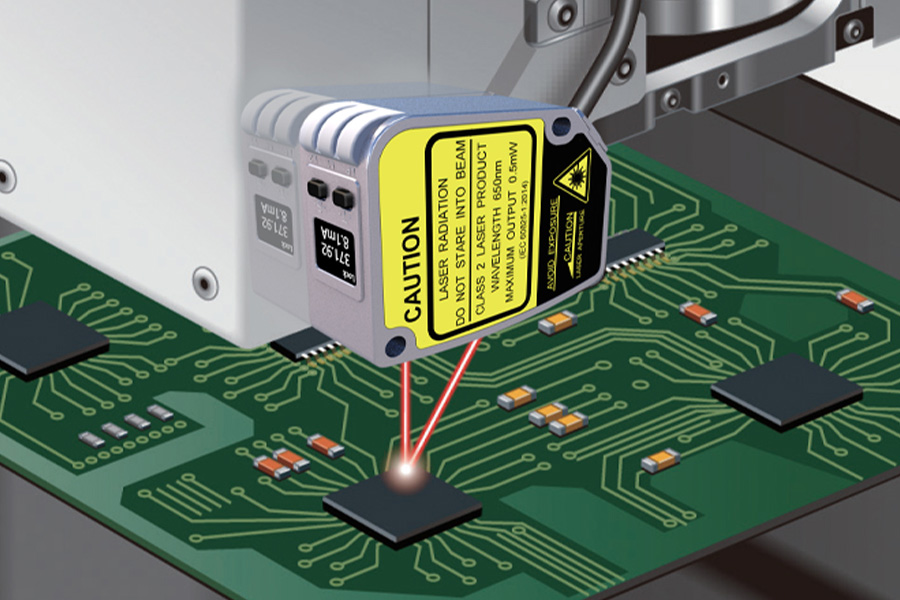

The core advantage of the FSD11 laser displacement sensor lies in its high adaptability to industrial scenarios. For precise positioning requirements of robotic arms, its base measurement range of 25-110mm covers most grasping operation ranges. Through a unique algorithm, it achieves a repeatability positioning accuracy of ±0.01mm, ensuring zero deviation in robotic arm movements during assembly and handling; In bottle cap gasket presence detection, it can quickly identify gasket contours below 0.5mm, preventing packaging seal failure due to missed inspections; in component thickness detection, it can stably output precise data even when faced with dimensional fluctuations as small as 0.1mm. This “broad scenario coverage + fine detail capture” capability enables the laser displacement sensor to maintain its core competitiveness across diverse operational conditions.

Performance breakthrough: precise distance measurement capability enhanced by unique algorithms

The precision of the FSD11 laser displacement sensor stems from breakthroughs in underlying technology. Its unique algorithms enable dynamic tracking of small objects. Even on high-speed production lines, where measured objects move at speeds of up to 1m/s, it maintains stable detection data. The basic measurement range supports 25-110mm, and can be expanded to 10-850mm via dual-button settings. This flexible measurement range adjustment feature allows the same device to detect both the thin structures of mobile phone components and the thick-walled workpieces of large machinery. For production lines requiring frequent switching of detection objects, the “multi-functional” characteristic of this laser displacement sensor significantly reduces equipment procurement costs.

Environmental Resistance: Dual Protection with IP67 Rating and Interference Resistance

The complex environments of industrial sites often pose challenges for inspection equipment, but the FSD11 laser displacement sensor easily handles such conditions with its dual-protection design. IP67-rated dust and water resistance is achieved through an automatic adhesive coating process, enabling the sensor to remain submerged in 1 meter of water for 30 minutes without affecting performance. This makes it ideal for humid environments in food processing facilities or oily production lines in automotive component manufacturing. Excellent EMC characteristics ensure it remains unaffected by electromagnetic or static interference, maintaining stable data output even in robot arm workstations with dense motor configurations. This “all-weather” capability allows the laser displacement sensor to overcome environmental limitations on application scenarios.

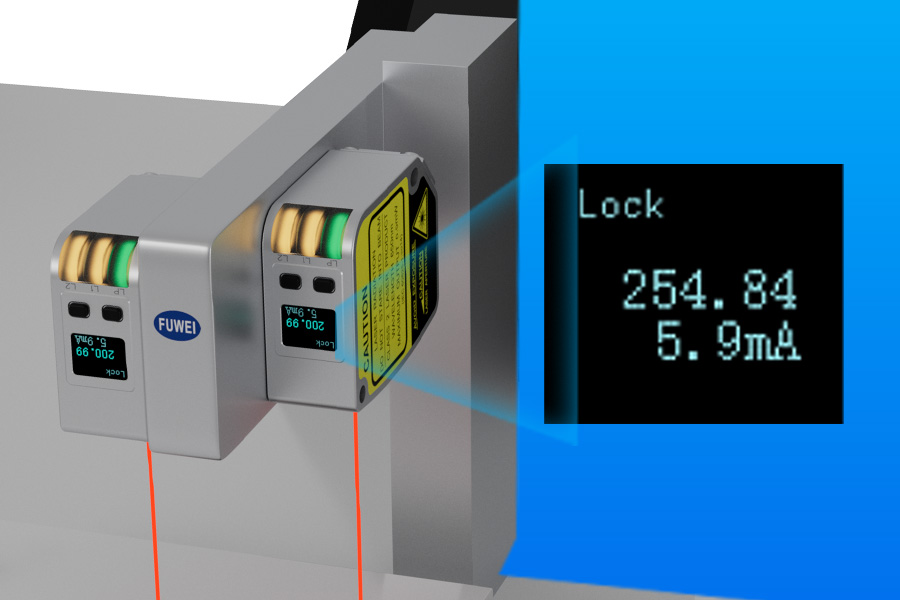

Operational Upgrades: Integrated Measurement and Control with Visualized Interaction for Enhanced Convenience

The FSD11 laser displacement sensor is designed with industrial site operational requirements in mind. An integrated processor enables combined measurement and control, eliminating the need for additional control modules, saving 50% of installation space at the end of the robotic arm, and reducing wiring work. The OLED display paired with a user-friendly control panel allows workers to complete range switching, output mode settings, and other operations within 30 seconds. Measurement data is displayed in real-time digital format, enabling parameter verification without connecting to a computer. This “plug-and-play” design significantly reduces equipment commissioning time.

Flexible Output: Multi-Mode Adaptability for Diverse Production Needs

To accommodate different production line control systems, the FSD11 laser displacement sensor offers a variety of output options. Switching output can directly trigger sorting mechanisms, quickly removing non-conforming products during bottle cap gasket inspection; analog output can integrate with PLC systems to achieve closed-loop control during robotic arm positioning, dynamically correcting positioning deviations. This “customizable” flexibility enables seamless integration into existing production systems, shortening equipment upgrade cycles.

From precise assembly in mechanical manufacturing to quality control in the packaging industry, the FSD11 laser displacement sensor combines precision, reliability, and convenience through scenario-based functional design. It is not only a high-performance laser displacement sensor but also a key device driving the quality and efficiency of industrial automation. In the pursuit of extreme precision in the industrial sector, it is emerging as the top choice for many enterprises with its robust capabilities.

No. 22, Hongyuan Road, Guangzhou, Guangdong Province, China

Copyright © 2024 Guangzhou Fuwei Electronic Technology Co., Ltd. All Rights Reserved.

Links | Sitemap | RSS | XML | Privacy Policy |