QR Code

About Us

Products

Contact Us

Phone

E-mail

Address

No. 22, Hongyuan Road, Guangzhou, Guangdong Province, China

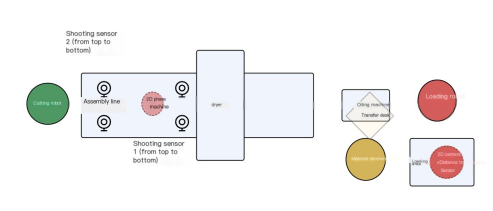

The solution of using composite robots to assist in oil brushing, drying, loading and unloading of aluminum alloy plates can significantly improve production efficiency, reduce errors and damages caused by human factors, and lower production costs. The following is a detailed explanation of the solution:

1、 Overview of the Plan

By utilizing the multifunctionality and high flexibility of composite robots, automated loading and unloading of aluminum alloy panels during oil brushing and drying processes can be achieved. Through precise programming and control systems, composite robots can complete the entire process from board loading, oil brushing, drying to unloading, thereby improving production efficiency, reducing manual operations, and lowering production costs.

2 Application of Composite Robots

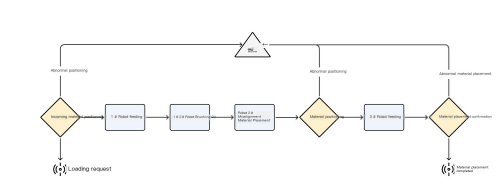

Automatic feeding: The composite robot is equipped with high-precision robotic arms and grasping devices, which can accurately grasp aluminum alloy plates and place them on the workbench of the oil brush machine. Through the visual system and sensors, the robot is able to recognize the position and posture of the board, ensuring accurate grasping.

Brush oil operation: The robot controls the brush oil machine to evenly brush the plate according to the preset program. By precise motion control and oil brushing parameter adjustment, the uniformity and consistency of the coating on the surface of the board can be ensured.

Drying treatment: After the oil brushing is completed, the composite robot moves the board to the drying equipment. During the drying process, the robot can adjust the drying time and temperature according to the status of the drying equipment and the properties of the board, ensuring that the board is completely dried without deformation.

Automatic cutting: After the drying is completed, the robot takes out the board from the drying equipment and places it in the designated cutting area. Through an automated cutting system, it is possible to achieve rapid collection and organization of panels, facilitating subsequent packaging and transportation.

3、 Advantages of the plan

Improve production efficiency: Composite robots can continuously and efficiently perform loading and unloading operations, reducing waiting time and errors in manual operations, significantly improving production efficiency.

Reduce production costs: By automating loading and unloading, labor costs are reduced, while errors and damages caused by human factors are also reduced, further lowering production costs.

Improving product quality: Robot operation has higher precision and stability, ensuring consistent quality of aluminum alloy panels during oil brushing and drying processes.

Flexibility and Scalability: Composite robots have high flexibility and scalability, and can be adjusted and optimized according to production needs to adapt to the processing of aluminum alloy sheets of different specifications and types.

The solution of using composite robots to assist in oil brushing, drying, loading and unloading of aluminum alloy plates can achieve efficient, accurate, and automated production processes, bringing significant economic and social be

No. 22, Hongyuan Road, Guangzhou, Guangdong Province, China

Copyright © 2024 Guangzhou Fuwei Electronic Technology Co., Ltd. All Rights Reserved.

Links | Sitemap | RSS | XML | Privacy Policy |