QR Code

About Us

Products

Contact Us

Phone

E-mail

Address

No. 22, Hongyuan Road, Guangzhou, Guangdong Province, China

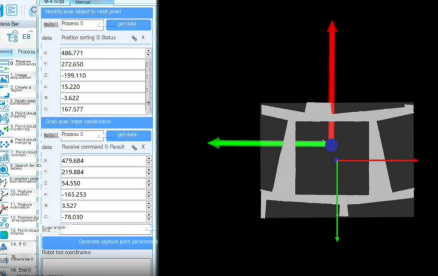

3D vision guided inertial ring for precise feeding

As the core component of automotive engine shock absorbers, the production process of inertia rings is particularly important in automotive parts factories. In the production workshop of the inertia ring, each workpiece needs to go through multiple fine processes such as casting, rough machining, precision machining, and specification re inspection to complete its magnificent transformation from raw materials to finished products. In this series of processing, the feeding of workpieces becomes an indispensable part of the production line. Therefore, ensuring efficient and precise feeding during the production process of inertial rings plays a crucial role in improving overall production efficiency and ensuring product quality.

3D vision guided inertial ring for precise feeding

·

Project Background

With the increasing demand for automation and intelligent production in the manufacturing industry, inertia rings, as an important mechanical component, have a wide range of applications in aviation, aerospace, automotive and other fields. However, traditional inertia ring feeding methods often rely on manual or pre programmed robots, which have limitations in dealing with complex shape, size, and position changes, resulting in low production efficiency, difficulty in ensuring accuracy, and high costs.

Project difficulties

The workpiece is circular in shape, with a reflective surface and covered with an oil film. The on-site environment has complex lighting, which places high demands on the imaging capability of 3D cameras;

The workpiece has a large size, multiple stacking layers, and high precision requirements for loading and unloading;

The value of workpieces and on-site equipment is expensive, and quality control standards are strict. Therefore, robots must achieve stable and precise loading and unloading operations, strictly avoiding any possible collisions or scratches to ensure the smooth progress of the production process and reduce potential losses;

The workpiece specifications are rich and diverse, with frequent updates and a compact and efficient production rhythm. To adapt to this change, the introduction of new product specifications must seamlessly integrate with existing production processes to ensure that production efficiency is not affected in any way.

Project advantages

Adopting advanced imaging algorithms, it can adapt to various lighting environments;

The Fuwei intelligent 3D camera with a large field of view and depth of field supports high-precision large-area operations. Suitable for scenarios such as large workpieces, large pallets, and deep frame grabbing;

Advanced visual algorithms, supporting over ten types of workpiece specifications. Quickly achieve flexible compatibility across multiple product specifications.

Core values:

Using the Fuwei intelligent robot to stably grasp the inertia ring significantly reduces cargo damage and improves production efficiency.

By introducing the Fuwei intelligent 3D vision solution, production capacity has increased threefold compared to before.

No. 22, Hongyuan Road, Guangzhou, Guangdong Province, China

Copyright © 2024 Guangzhou Fuwei Electronic Technology Co., Ltd. All Rights Reserved.

Links | Sitemap | RSS | XML | Privacy Policy |