QR Code

About Us

Products

Contact Us

Phone

E-mail

Address

No. 22, Hongyuan Road, Guangzhou, Guangdong Province, China

With the continuous improvement of industrial automation level, as an important gas compression equipment in the industrial field, the demand for automated feeding of air compressors is becoming increasingly prominent. In order to improve production efficiency and reduce labor intensity, we propose an automated feeding solution for air compressors based on 3D vision guidance.

Overview of the Plan

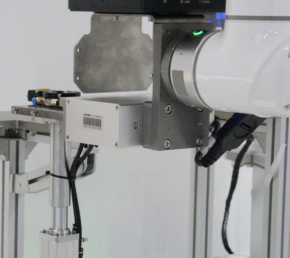

This solution mainly includes parts such as 3D vision system, robot arm, control system, etc. Among them, the 3D vision system is used to obtain the position and posture information of the air compressor feeding, the robot arm accurately grasps and places according to the information provided by the vision system, and the control system is responsible for the coordination and scheduling of the entire system.

technical realization

3D vision system: using high-precision 3D cameras and corresponding algorithms, real-time acquisition of the position and posture information of the air compressor, and generation of the robot's grasping path. At the same time, the 3D vision system can also monitor the grasping process in real time to ensure the accuracy and stability of the grasping.

Robot arm: High precision and high stability robot arms are selected to accurately grasp and place the air compressor according to the grasping path provided by the 3D vision system. At the same time, the robotic arm also has self-learning ability and can continuously optimize grasping strategies based on actual production situations.

Control system: Advanced industrial control systems are used to uniformly manage and schedule equipment such as robot arms and 3D vision systems. The control system can receive production instructions in real time, adjust the operation status of the robot according to production needs, and ensure the efficiency and stability of production.

Advantages of the plan

High efficiency: Through automated feeding, the production efficiency of the air compressor has been significantly improved, reducing production costs.

High precision: Utilizing 3D vision technology for precise positioning and recognition, ensuring the accuracy of grasping and placement.

Flexible production: By adjusting the parameters of the visual system and robot arm, it is possible to adapt to the feeding requirements of different models and specifications of air compressors, achieving flexible production.

Safe and reliable: Automated feeding reduces the labor intensity and safety risks of manual operations, and improves the safety and reliability of production.

Easy to maintain: The entire system adopts a modular design, which facilitates daily maintenance and troubleshooting.

The 3D vision guided automatic feeding solution for air compressors has advantages such as high efficiency, high precision, flexible production, safety and reliability. In practical applications, this solution will help improve the production efficiency and product quality of air compressors, reduce production costs and manual operation risks.

No. 22, Hongyuan Road, Guangzhou, Guangdong Province, China

Copyright © 2024 Guangzhou Fuwei Electronic Technology Co., Ltd. All Rights Reserved.

Links | Sitemap | RSS | XML | Privacy Policy |