QR Code

About Us

Products

Contact Us

Phone

E-mail

Address

No. 22, Hongyuan Road, Guangzhou, Guangdong Province, China

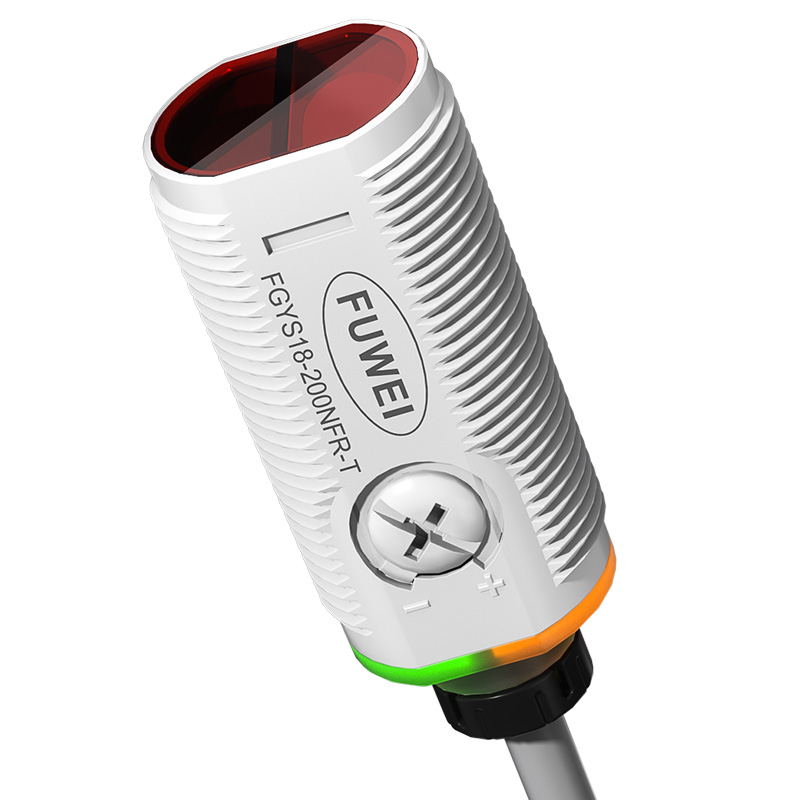

In modern industrial automation, accurately and reliably detecting transparent packaging remains a significant challenge. The introduction of the FGYS18-200NFR-T lens-reflection photoelectric sensor provides a groundbreaking technological breakthrough. Specifically optimized for transparent object detection, this sensor redefines the reliability standards for

industrial detection equipment through multiple protection mechanisms and optical innovations.

Triple Protection Shield for Maximum Safety

The sensor's built-in short-circuit protection module can cut off the circuit within milliseconds if a short circuit occurs in the output signal or power lines, effectively preventing cascade damage from current overload. Its unique reverse polarity protection circuit eliminates installation constraints found in traditional sensors; even if a novice engineer mistakenly reverses the positive and negative poles, it will not cause component burnout. Coupled with an over-voltage protection system that automatically activates a voltage stabilization mechanism when circuit voltage exceeds a preset threshold, this triple protection ensures the transparent bottle detection sensor maintains stable operation even in harsh industrial environments.

Optical Innovation for Precise Transparent Material Capture

Utilizing coated filter lens technology, the sensor accurately filters out stray ambient light interference. Its integrated visible red light spot system, combined with an adjustable detection range of up to 2 meters, allows technicians to visually identify the optimal detection point for transparent bottles. It is particularly noteworthy that this advanced transparent bottle detection sensor employs a quartz material lens with a near-zero thermal expansion coefficient. This ensures consistent optical performance within an operating temperature range of -25°C to 55°C, fundamentally solving the detection drift issues common in traditional sensors caused by thermal deformation.

Performance Redefining Detection Standards

In real-world tests on beverage filling production lines, the sensor demonstrated remarkable stability when detecting high-speed moving PET transparent bottles. Its coated lens effectively distinguishes between the bottle body and background based on refractive index differences, achieving a 300% improvement in anti-interference capability compared to conventional products. This professional-grade transparent bottle detection sensor not only solves the industry-wide challenge of missing transparent containers but also maintains a false detection rate below 0.05%. After 2000 hours of continuous stress testing, the sensor's core components showed no signs of performance degradation, making this durable transparent bottle detection sensor the preferred choice for high-demand production scenarios.

As Industry 4.0 advances, demands for detection precision are becoming increasingly stringent. Integrating multiple technologies—circuit protection, optical optimization, and temperature compensation—this sensor not only provides a perfect solution for transparent packaging detection but also represents the evolution of industrial sensors towards intelligent and highly reliable systems. Its forward-looking technology indicates that the next generation of transparent bottle detection sensors will continue evolving with smarter self-diagnostic capabilities and more

No. 22, Hongyuan Road, Guangzhou, Guangdong Province, China

Copyright © 2024 Guangzhou Fuwei Electronic Technology Co., Ltd. All Rights Reserved.

Links | Sitemap | RSS | XML | Privacy Policy |