QR Code

About Us

Products

Contact Us

Phone

E-mail

Address

No. 22, Hongyuan Road, Guangzhou, Guangdong Province, China

The Fuwei intelligent robot assembly line pallet loading and unloading solution is a comprehensive solution that integrates advanced robot technology and automation control system, aiming to improve production line efficiency, reduce manual intervention, lower operating costs, and enhance the stability and reliability of the production process.

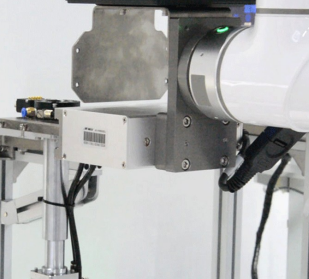

The core of this solution is to use Fuwei intelligent robots to achieve automatic loading and unloading of pallets. These robots can accurately remove trays from the assembly line and place them in designated positions, or grab trays from storage areas onto the assembly line for subsequent processing, through precise positioning and gripping technology.

Specifically, the Fuwei intelligent robot assembly line pallet loading and unloading solution includes the following key steps:

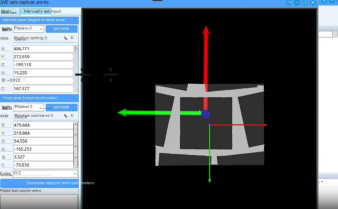

1. Robot positioning and navigation: By utilizing advanced visual recognition systems and sensor technology, robots can accurately identify the position, posture, and quantity of pallets on the assembly line. Meanwhile, through autonomous navigation systems, robots are able to autonomously plan their paths, achieving precise movement and positioning.

2. Tray grabbing and handling: The robot is equipped with a specialized grabbing mechanism that can adaptively adjust according to the size, shape, and weight of different trays. Through precise grasping and handling actions, the robot can ensure the stability and safety of the pallet during the loading and unloading process.

3 Pipeline docking and collaboration: Fuwei intelligent robots can seamlessly dock with the pipeline to achieve collaborative operations. Robots can automatically adjust their movement speed and frequency according to the speed and rhythm of the assembly line, ensuring the continuity and efficiency of the loading and unloading process.

4 Intelligent Management and Control System: This solution also includes an intelligent management and control system for real-time monitoring and management of the robot's operating status and job data. Through data analysis and optimization algorithms, the system can automatically adjust the working parameters and strategies of the robot, improving the overall efficiency and performance of the production line.

By implementing the Fuwei intelligent robot assembly line pallet loading and unloading solution, enterprises can achieve the following advantages:

Improve production efficiency: Robots can continuously and efficiently perform pallet loading and unloading operations, reducing manual intervention and waiting time, and improving the overall efficiency of the production line.

Reduce operating costs: By reducing manpower input and lowering labor costs, companies can significantly lower operating costs. Meanwhile, the consistency and accuracy of robot operations also contribute to reducing product defects and waste.

Enhance production stability: Robot operations are not affected by human factors, ensuring the stability and reliability of the production process. Even in harsh working environments, robots can maintain efficient and stable working conditions.

Improving safety: Robots replace manual labor for pallet loading and unloading operations, reducing the risk of employee injury and enhancing workplace safety.

In summary, the Fuwei intelligent robot assembly line pallet loading and unloading solution is an efficient, reliable, and intelligent automation solution that helps enterprises upgrade and transform their production lines, enhance competitiveness, and market share.

No. 22, Hongyuan Road, Guangzhou, Guangdong Province, China

Copyright © 2024 Guangzhou Fuwei Electronic Technology Co., Ltd. All Rights Reserved.

Links | Sitemap | RSS | XML | Privacy Policy |