QR Code

About Us

Products

Contact Us

Phone

E-mail

Address

No. 22, Hongyuan Road, Guangzhou, Guangdong Province, China

Composite robots are playing an increasingly important role in the automotive manufacturing industry. These robots, which integrate multiple advanced technologies, can not only improve production efficiency but also significantly reduce manufacturing costs, becoming a new driving force for the sustainable development of the automotive manufacturing industry.

1、 Technical characteristics of composite robots

A composite robot is an intelligent robot that integrates multiple functions, incorporating various technologies such as mechanics, electronics, computers, and artificial intelligence. In the automotive manufacturing industry, composite robots can complete various tasks such as welding, assembly, and inspection, and have the following significant characteristics:

1 Highly integrated: Composite robots integrate multiple functions on a single platform, achieving the goal of completing multiple tasks with a single device and improving device utilization.

2 High precision: The composite robot adopts advanced control system and sensor technology to achieve high-precision operation and ensure product quality.

3. High efficiency: Composite robots can continuously and quickly complete various tasks, greatly improving production efficiency.

Flexibility: Composite robots can be quickly adjusted according to production needs, adapting to the production requirements of different vehicle models and processes.

2、 Application of Composite Robots in the Automotive Manufacturing Industry

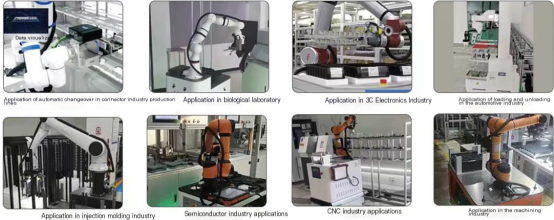

In the automotive manufacturing industry, the application of composite robots has penetrated into various links of the production line. Here are several typical application cases:

Assembly process: Composite robots can complete the assembly tasks of various components, reducing manual operations and improving assembly speed and accuracy.

Testing process: Composite robots can perform tasks such as quality inspection and size measurement, ensuring product consistency and reliability.

3、 The impact of composite robots on the automotive manufacturing industry

The application of composite robots in the automotive manufacturing industry has had a profound impact on production processes, cost control, and product quality

Optimize production process: The introduction of composite robots makes the production process more compact and efficient, reducing waiting time and idle time on the production line.

Reducing manufacturing costs: The high degree of automation and intelligence of composite robots significantly reduces labor costs, equipment depreciation, and other expenses, enhancing the competitiveness of enterprises.

Improving product quality: The high-precision and high-efficiency operation of composite robots ensures the consistency and stability of product quality, and enhances customer satisfaction.

In short, composite robots have become a new driving force for cost reduction and efficiency improvement in the automotive manufacturing industry. In the face of future market competition and challenges, we should actively explore the application and development trends of composite robots to promote continuous innovation and development of enterprises.

No. 22, Hongyuan Road, Guangzhou, Guangdong Province, China

Copyright © 2024 Guangzhou Fuwei Electronic Technology Co., Ltd. All Rights Reserved.

Links | Sitemap | RSS | XML | Privacy Policy |