QR Code

About Us

Products

Contact Us

Phone

E-mail

Address

No. 22, Hongyuan Road, Guangzhou, Guangdong Province, China

As an important component of automobiles, the assembly process of rear shock absorbers requires a high degree of precision and stability. The traditional assembly method often relies on manual operation, which is not only inefficient but also susceptible to human factors, leading to unstable assembly quality. The introduction of composite robots has completely changed this situation.

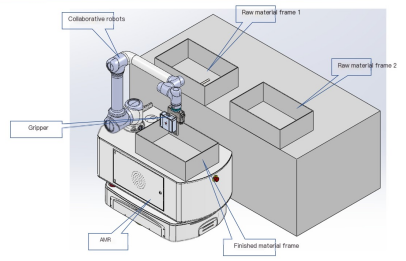

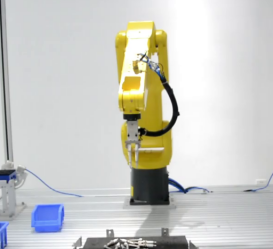

Composite robots combine the functions of movement and operation, allowing them to move freely in complex production environments and perform various delicate assembly tasks. Through advanced vision systems and sensor technology, composite robots can accurately identify the various components of the rear shock absorber and precisely control the robotic arm for grasping and placing. This high-precision operational capability ensures that each component can be assembled according to design requirements, greatly improving the accuracy and stability of assembly.

In addition, composite robots also have strong programming and learning capabilities. Through pre-set programs, robots can autonomously complete the entire assembly process without the need for human intervention. At the same time, robots can also self adjust and optimize according to actual production situations, continuously improving assembly efficiency and quality. This intelligent feature enables composite robots to perform excellently in dealing with complex and ever-changing assembly tasks.

In addition to improving assembly efficiency and accuracy, composite robots can also reduce production costs and labor risks. Due to the ability of robots to replace manual labor for repetitive and tedious assembly operations, labor costs can be significantly reduced. At the same time, the consistency and stability of robot operation also reduce production errors and defect rates caused by human factors. In addition, robots can perform long-term operations in harsh working environments, further improving the reliability and stability of production.

What are the advantages of the Fuwei intelligent composite robot in the assembly of rear shock absorbers?

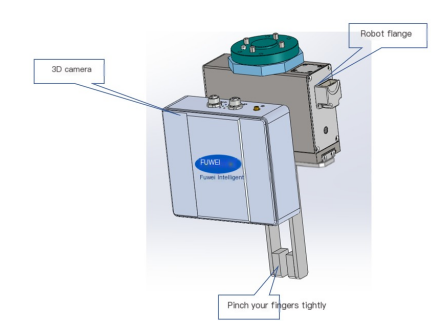

Automated grasping and placement: The composite robot has a highly flexible robotic arm and precise grasping device, which can automatically identify and accurately grasp various components of the rear shock absorber. Through advanced vision systems and sensor technology, robots can obtain real-time position and posture information of components, achieving high-precision grasping and placement operations.

High precision assembly: During the assembly process of the rear shock absorber, there are strict requirements for the assembly accuracy of the components. Composite robots can ensure that each component is assembled according to design requirements through high-precision control systems and motion trajectory planning, achieving high-precision manufacturing of rear shock absorbers.

Quality inspection and feedback: The composite robot is not only responsible for assembly, but also capable of conducting quality inspections on the assembled rear shock absorbers. By integrating multiple sensors and detection devices, the robot can detect various performance indicators of the rear shock absorber, such as damping performance, stability, etc., to ensure that the product meets quality standards. At the same time, the robot can also provide real-time feedback on the detection results to the control system, achieving continuous optimization of the assembly process.

Efficient collaborative operation: During the assembly process of the rear shock absorber, the composite robot can achieve efficient collaborative operation with other automated equipment. Through wireless communication and collaborative control technology, robots can share information and coordinate actions with other devices, achieving automation and intelligence in the assembly process.

Composite robots have revolutionized the assembly process of rear shock absorbers through automated grasping and placement, high-precision assembly, quality inspection and feedback, and efficient collaborative work. This not only improves assembly efficiency and product quality, but also reduces labor costs and operational risks, providing strong support for the upgrading and transformation of the rear shock absorber manufacturing industry.

No. 22, Hongyuan Road, Guangzhou, Guangdong Province, China

Copyright © 2024 Guangzhou Fuwei Electronic Technology Co., Ltd. All Rights Reserved.

Links | Sitemap | RSS | XML | Privacy Policy |